Piezoelectric motors

Piezoelectric elements generally provide very high forces, but have very limited stroke. Through the addition of individual steps, continuous rotatory and larger translatory motion can be achieved. Various mechanisms are presented as follows.

Piezoelectric Inertial motors

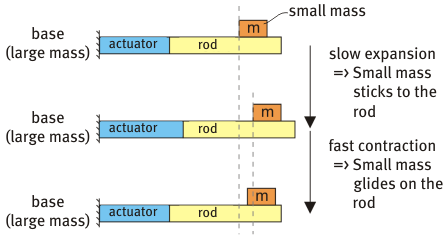

The problem of the low stroke of piezoelectric solid-state actuators is solved in piezoelectric inertial motors by the accumulation of several small steps so that an unlimited stroke is basically achieved. The picture shows a rather simple working principle: during slow movement, the moving mass is held to a base plate by frictional force, which is then displaced by a piezoelectric actuator. It slides during the fast return stroke and remains displaced by a small distance per cycle.

Inertial motors exist as both translatory and rotary drives in a variety of designs. In literature these are also referred to as a "stick-slip drive" or "impact drive".

The first inertial motors were developed as high-precision positioning devices for use in microscopy, e.g. in scanning tunneling microscopes. Inertia motors for such applications are mostly individual components and because of their application purpose, they are not particularly small or optimized in terms of load bearing capacity or speed. Inertial motors have been presented for other applications in recent years, where the main focus lies on speed, economy, reliability, simplicity and good miniaturization. Such motors are used in applications such as zoom lenses of mobile phones and PDA-cameras or in anti-shake mechanisms in digital cameras.

Several questions need to be answered during the development of a piezoelectric inertial motor: How large are the moving masses? What kind of pressure is applicable? How are the friction surfaces to be designed? With which electrical signal is the motor controlled, at which frequency? These questions are currently answered by the construction and testing of prototypes. This process is time-consuming and costly, and an effective application-specific design of the motors is thus not possible. Modeling approaches, for example as described in [Hunstig 2014] offer substantial advantages here.

Piezoelectric vibration drives

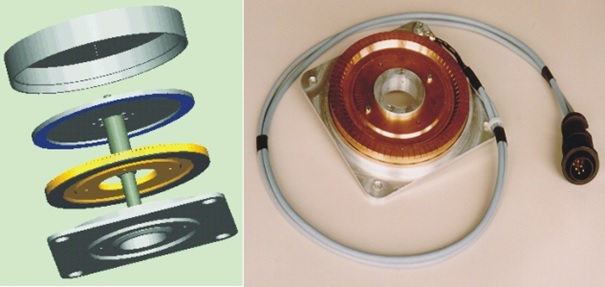

In rotary traveling-wave motors, the circular-ring-shaped stator is excited by means of piezoelectric actuators to bending oscillations in the form of circumferential waves. Thus, the material surface points of the stator move along elliptical paths. At maximum deflection, they have a velocity component in the circumferential direction, which causes the pressed rotor to rotate. The oscillation excitation takes place at a resonance frequency of the stator in the ultrasonic range. Oscillation amplitudes of a few micrometers are achieved, which are frictionally converted into a continuous rotational motion. Typical performance for today's traveling-wave motors are a torque of up to 2 Nm and speeds of around 100 rpm.

The working principle gives the drives a series of favorable features, which makes them an attractive alternative to classic electric drives in many applications. Particularly interesting are the simple mechanical design and the generation of high torques and active powers at low speeds, which often means that an additional gear unit can be dispensed with. Further advantages are the high holding torque when the power supply is switched off, the high dynamics and the high precision in fine positioning.

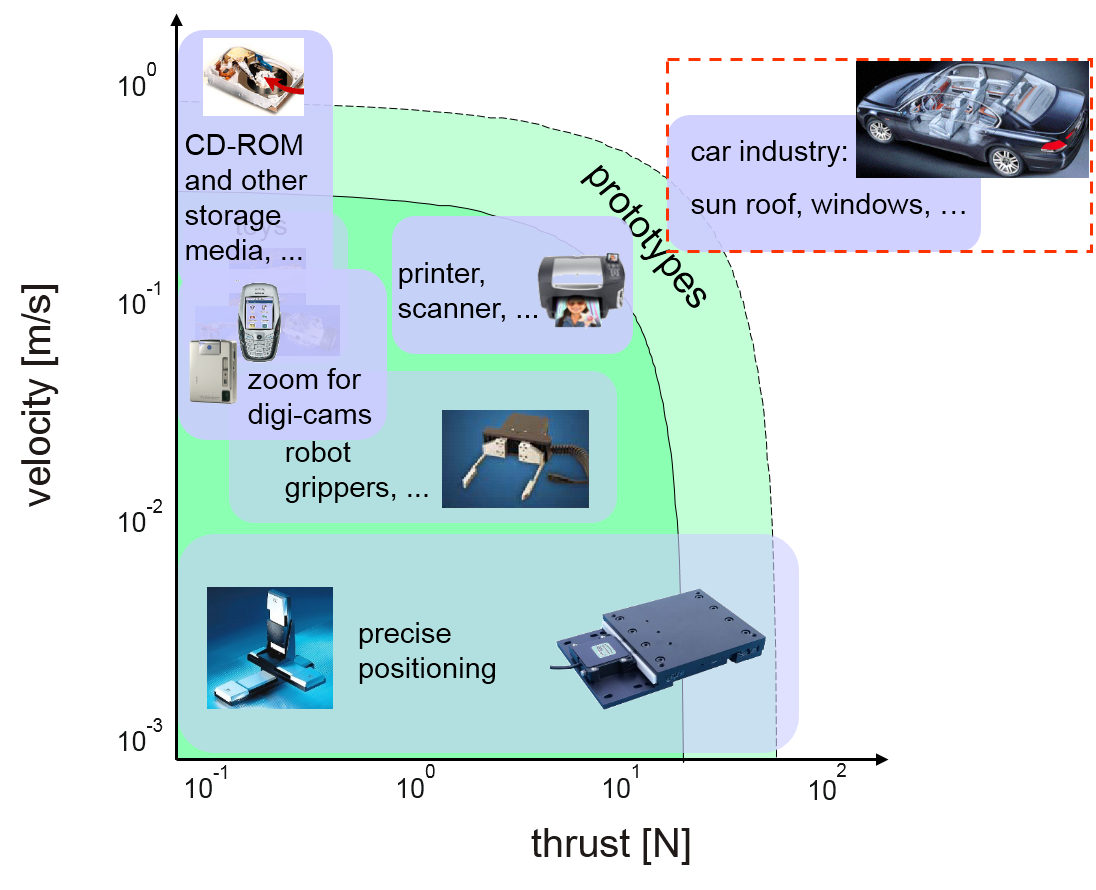

The precise generation of translational and linear motions is an important task of modern technology. Classic application examples are the positioning axes of production machines, windows and sunroofs in motor vehicles. In home appliances, such as CD player, it is also necessary to move the trays linearly or position the read and write heads of disks.

Vibration drives can generate translational motion directly without a gearbox. This results in the following advantages compared to the conventional rotary-motor-gearbox solution:

- No gear losses, thus high overall efficiency

- Small number of components

- Little required installation space

- No reversal or lots

- Good dynamics

- Motor step resolution in the range of a few nanometers

Since the mid-1990s, translational piezoelectric vibration drives became commercially available. Up to now, forces up to 40 N and propulsion speeds up to 300 mm/s can be achieved. This results in a wide field of possible applications, but this has not yet been fully exploited. In addition, performance data are not sufficient for many other tasks.

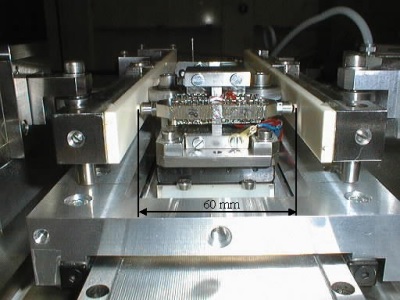

In the course of our work, we investigated the basically conceivable and practically usable functions and types of linear vibration drives. The "rowing" principle, in which forces are taken at two opposite points of an actuator, has been recognized as promising. On the basis of several prototypes, different designs were characterized in terms of their performance. Optimized drives are being designed, built and applied in various applications.

Publications on this research area can be found here.