Geometry optimization of bonding tools

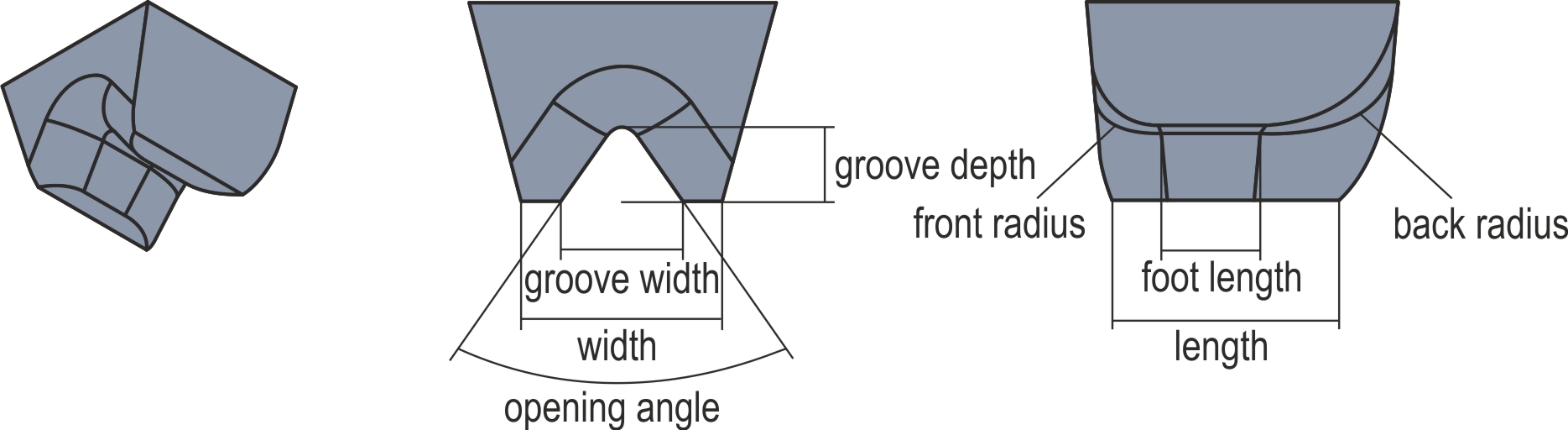

The bonding tool is used in ultrasonic wire bonding to transmit the oscillatory movement to the wire. The tip of bonding tools is usually designed so that the wire is guided laterally. By applying a normal force, the wire is first pressed into the groove of the bonding tool and the vibration is then transferred to the wire in a frictional manner during bonding. The wire first rubs on the substrate and after it has been bonded, there is partially slippage between the bonding tool and the wire. The imprinted normal force, the geometry-dependent transferable tangential force of the bonding tool and the ultrasonic movement have a significant influence on the wire deformation and the bond formation.

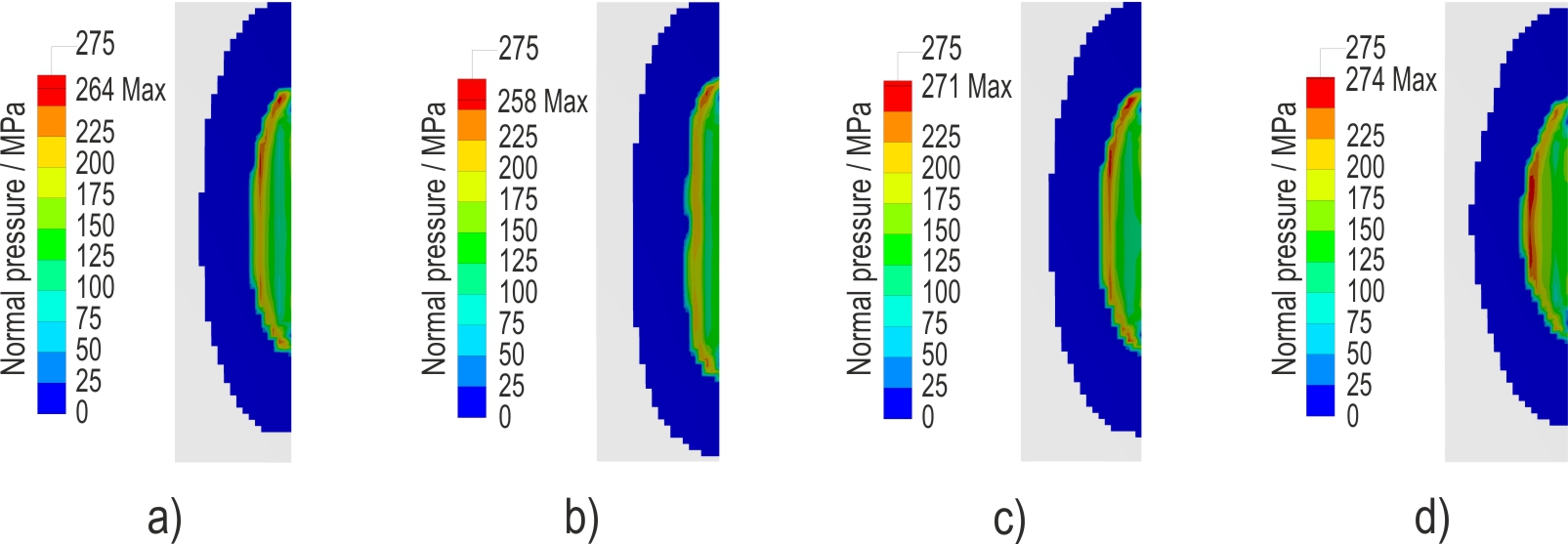

Finite element simulations show the influence of the geometry of the bonding tool on the wire geometry. In addition to the opening angle, the groove width and groove depth have a direct influence on the resulting geometry of the wire. There are different approaches for optimization. The force transmission between the bonding tool and wire and the contact area of the wire and substrate can be varied. This results in potential to increase the efficiency of the bonding process for robust substrates or to reduce the stresses during bonding in order to protect sensitive substrates.

These investigations are carried out in close cooperation with Infineon Technologies AG.

You can find publications on this topic here.