Ultrasonic Powder Transport

The transport of fine powders with particle sizes of a few micrometers is a technological challenge. Due to the adhesive forces of ultrafine powders, common transport mechanisms such as vibratory conveyors fail.

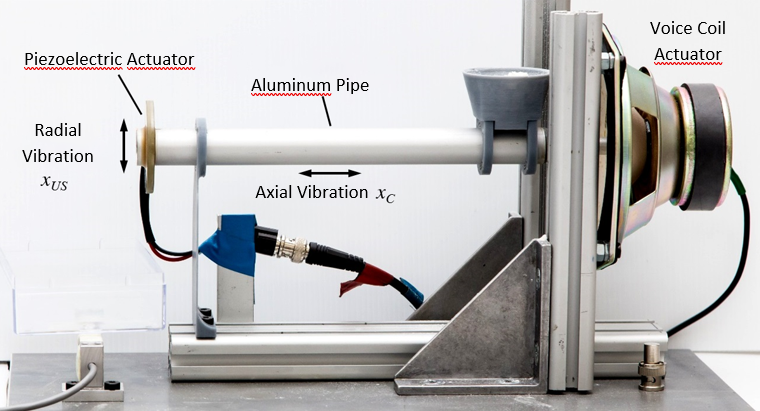

A relatively new principle for the transport of these fine powders is based on ultrasonic vibrations, which are used to reduce the effective coefficient of friction between powder and substrate. The carrier (e.g. pipe or trough) is excited to a low-frequency harmonic vibration in the direction of transport. By coordinated switching on and off of an additional ultrasonic oscillation, the effective coefficient of friction between powder and conveyor is manipulated in such a way that the powder is strongly accelerated in one direction with a high effective coefficient of friction and only slightly decelerated in the other direction with a reduced effective coefficient of friction. A sequence of such oscillation periods enables continuous powder transport.

The operation principle is suitable both for large powder flows and for fine dosing. In order to determine the appropriate operating parameters (amplitudes of the vibrations, switching times, pipe material), a model has been built. This enables, for example, targeted maximization of the conveying speed by setting optimized time switching points.

You can find publications on powder transport here.