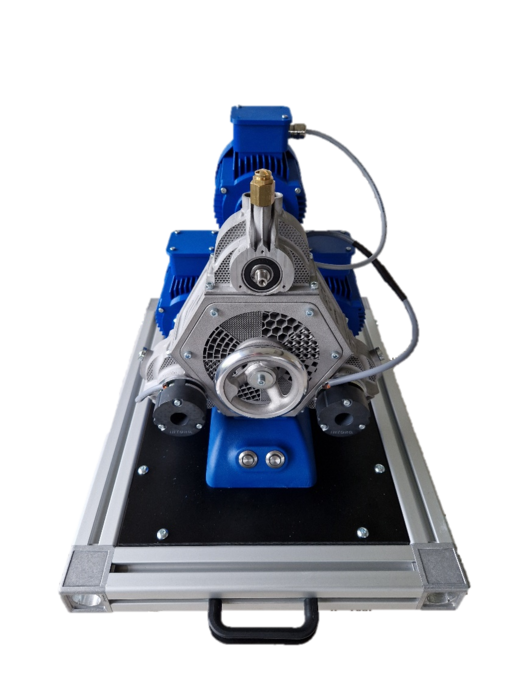

The KAt chair has successfully recreated the chair's own research platform ‘KAtAMaran’ (construction and drive technology in AM-optimised modular drive) on a scale of 1:2 as a functional miniature demonstrator ‘KAtAMini’. The miniature demonstrator is used as an application example in lectures to illustrate design aspects of additive manufacturing and demonstrate the function of machine elements, motors and brakes. Thanks to its miniaturised and battery-powered design, it also enables mobile use in lecture halls and seminar rooms.

Students can now better grasp the theoretical learning content as it relates to a real-life assembly that is used in the exercises throughout the semester. The miniature demonstrator enables students to understand the connection between a technical drawing, a CAD model and the real components and to link theoretically orientated teaching content with real components. In addition, another modular, interchangeable drive unit was realised to familiarise students with various bearing concepts. These include a locating/non-locating bearing arrangement with deep groove ball bearings, as well as angled bearing arrangements in an X or O arrangement with tapered roller bearings. The housing and shaft were designed so that all three bearing arrangements can be mounted without the need for additional shafts or housings. The open design of the housing allows students to view the elements in (self) installed condition and to learn various assembly aspects.

In addition, various additive manufacturing processes were used in the production of the miniature demonstrator in order to give students a feel for these processes and to understand their possible applications and limitations as early as the foundation course. Production using laser beam melting, laser sintering and fused deposition modelling was carried out on the KAt systems as well as at the Direct Manufacturing Research Center (DMRC) - academic and the StudentLab3D.

Diese umfassen eine Fest-Los-Lagerung mit Rillenkugellagern sowie angestellte Lagerungen in X- oder O-Anordnung mit Kegelrollenlagern. Das Gehäuse und die Welle wurden so gestaltet, dass alle drei Lageranordnungen montierbar sind, ohne zusätzliche Wellen oder Gehäuse zu benötigen. Die offene Gestaltung des Gehäuses ermöglicht es den Studierenden, die Elemente im (selbst) eingebauten Zustand zu betrachten und verschiedene Montageaspekte zu erlernen.

Darüber hinaus wurden verschiedene additive Fertigungsverfahren bei der Herstellung des Miniaturdemonstrators angewendet, um den Studierenden bereits im Grundlagenstudium ein Gefühl für diese Verfahren zu vermitteln und ihre Einsatzmöglichkeiten und Grenzen zu verstehen. Die Fertigung mittels Laser-Strahlschmelzen, Lasersintern und Fused Deposition Modeling erfolgte auf den Anlagen des KAt sowie am Direct Manufacturing Research Center (DMRC) – academic und dem StudentLab3D.