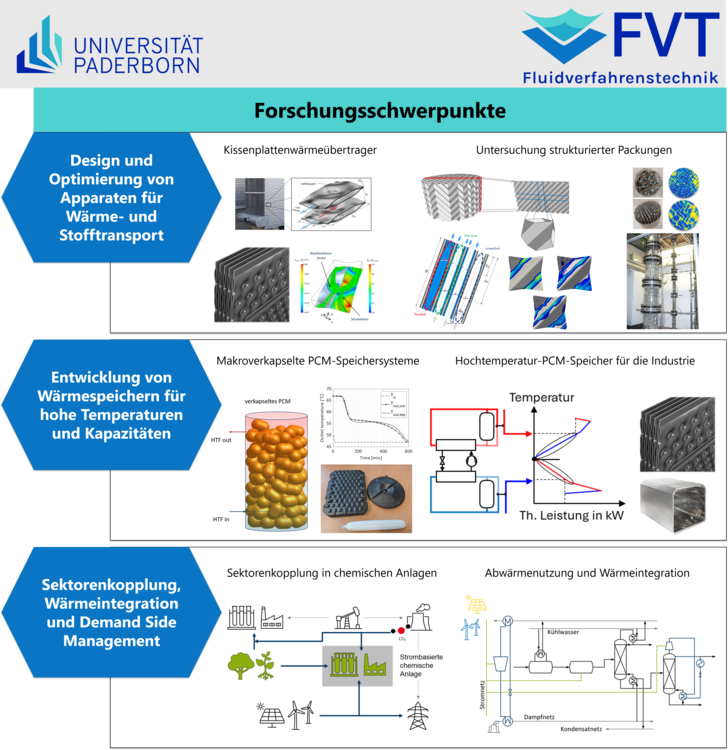

Design and optimisation of apparatus for heat and mass transfer

Efficient equipment for heat and mass transport forms the basis for efficient and therefore resource-saving processes. In addition to a basic understanding of the elementary transport processes with the aid of numerical methods, we dedicate ourselves to the experimental investigation and optimisation of the apparatus and unit operations. A particular focus here is on energy-efficient heat exchangers and non-reactive and reactive separation apparatus. In the field of heat exchangers, we are particularly investigating pillow plate apparatuses which, due to their geometry, promise an intensification of heat transfer with simple scaling at the same time. In the field of separators, we are working intensively on the use of structured packings as separating internals. Our interest ranges from the detailed elucidation of the liquid topology on the microstructured sheets to the integral experimental characterisation of fluid dynamics and mass transfer.

Below you will find some recent publications from this research area:

- R. Afsahnoudeh, A. Wortmeier, M. Holzmüller, Y. XGong, W. Homberg, E.Y. Kenig: Thermo-hydraulic Performance of Pillow-Plate Heat Exchangers with Secondary Structuring: A Numerical Analysis, 2023, https://doi.org/10.3390/en16217284

- C. Dechert, I.M. Baumhögger, E.Y. Kenig: CFD-based investigation of the efficiency enhancement due to microstructure reorientation in structured packing, 2024, https://doi.org/10.1016/B978-0-443-28824-1.50005-3

- P. Franke, I. Shabanilemraski, M. Schubert, U. Hampel, E.Y. Kenig: A new approach to model the fluid dynamics in sandwich packings, 2024, https://doi.org/10.1515/cppm-2023-0054

- J. Riese, A. Reitze, M. Grünewald: Experimental Characterisation of 3D Printed Structured Metal Packing with an Enclosed Column Wall, 2022, https://doi.org/10.1002/cite.202200002

- H. Fasel, M. Grünewald, J. Riese: On the lower operation limit and the gain of flexibility of an innovative segmented tray column, 2022, https://doi.org/10.1002/amp2.10144

- F. Herrmann, M. Grünewald, J. Riese: Model-based design of a segmented reactor for the flexible operation of the methanation ofCO2, 2022, https://doi.org/10.1016/j.ijhydene.2022.12.122

Development of heat accumulators for high temperatures and capacities

In order to increase the share of renewable energy sources in the field of heat supply, appropriate technologies for energy conversion as well as options for energy storage or heat storage are required. One technical solution is the use of latent heat storage systems in which the thermal energy is stored or released through the phase change of a specific material (phase change material, PCM). These PCM materials can exist in different forms and determine the storage temperature through their physical properties. We develop appropriate latent heat storage systems for different applications and analyse them with the help of theoretical and experimental studies. In our current work, we are focusing on the development of high-temperature heat storage systems for industrial use and macro-encapsulated PCM storage systems with increased capacity for use in residential buildings and neighbourhoods.

Previous publications from this research focus:

- M. Grabo, E. Acar, E. Kenig: Modelling and improvement of a packed bed latent heat storage filled with non-spherical encapsulated PCM-Elements, 2021, https://doi.org/10.1016/j.renene.2021.04.022

- M. Grabo, C. Staggenborg, K.A. Philippi, E. Kenig: Modeling and Optimisation of Rectangular Latent Heat Storage Elements in an Air-Guided Heat Storage System, 2020 , doi.org/10.3389/fenrg.2020.571787

- M. Grabo, D. Weber, A. Paul, T. Klaus, W. Bermpohl, S. Krauter, E. Kenig: Numerical Investigation of the Temperature Distribution in PCM-integrated Solar Modules, 2019, https://doi.org/10.3303/CET1976150

Sector coupling, heat integration and demand side management

The coupling of the energy system and industrial production goes far beyond the topic of heat storage. One building block is the utilisation of chemical energy sources as a coupling element. Here we are looking at the production of synthetic natural gas fromCO2 and hydrogen and the challenge of optimising the design and operation of the necessary power-to-gas plants in line with the prevailing local conditions. Another building block is the integration of heat pumps and storage systems into industrial production processes. There is a lack of heuristics and evaluation methods that identify possible integration points and evaluate potential integration quickly and with little effort. Another building block is demand side management, which describes the adaptation of process management to the boundary conditions of the energy system, in particular volatile electricity prices. Challenges exist here in particular with regard to the integration of DSM programmes in processes in the (bio)chemical industry.

Further literature on this research focus:

- B. Bruns, M. Gross, M. Grünewald, V. Bertsch, J. Riese: A multi-step framework for the design of a flexible power-to-methane process, 2024, https://doi.org/10.1016/j.jclepro.2024.141434

- L.S. Röder, A. Gröngröft, M. Grünewald, J. Riese: Optimisation of Design and Operation of a Digestate Treatment Cascade for Demand Side Management Implementation, 2024, https://doi.org/10.1016/j.compchemeng.2024.108838

- T. Hochhaus, B. Bruns, M. Grünewald, J. Riese: Optimal scheduling of a large-scale power-to-ammonia process: Effects of parameter optimisation on the indirect demand response potential, 2023 , doi.org/10.1016/j.compchemeng.2023.108132

- L. Röder, H. Etzold, A. Gröngröft, M. Grünewald, J. Riese: Decision support tool to determine the suitability of demand side management implementation in continuously operated processes - A biorefinery case study, 2023, https://doi.org/10.1002/bbb.2558

- F. Herrmann, M. Grünewald, T. Meijer, U. Gardemann, L. Feierabend, J. Riese: Operating window and flexibility of a lab-scale methanation plant, 2022, https://doi.org/10.1016/j.ces.2022.117632

- A. Di Pretoro, B. Bruns, S. Negny, M. Grünewald, J. Riese: Demand response scheduling using derivative-based dynamic surrogate models, 2022, https://doi.org/10.1016/j.compchemeng.2022.107711