Absorption-desorption pilot plant for CO2-capture

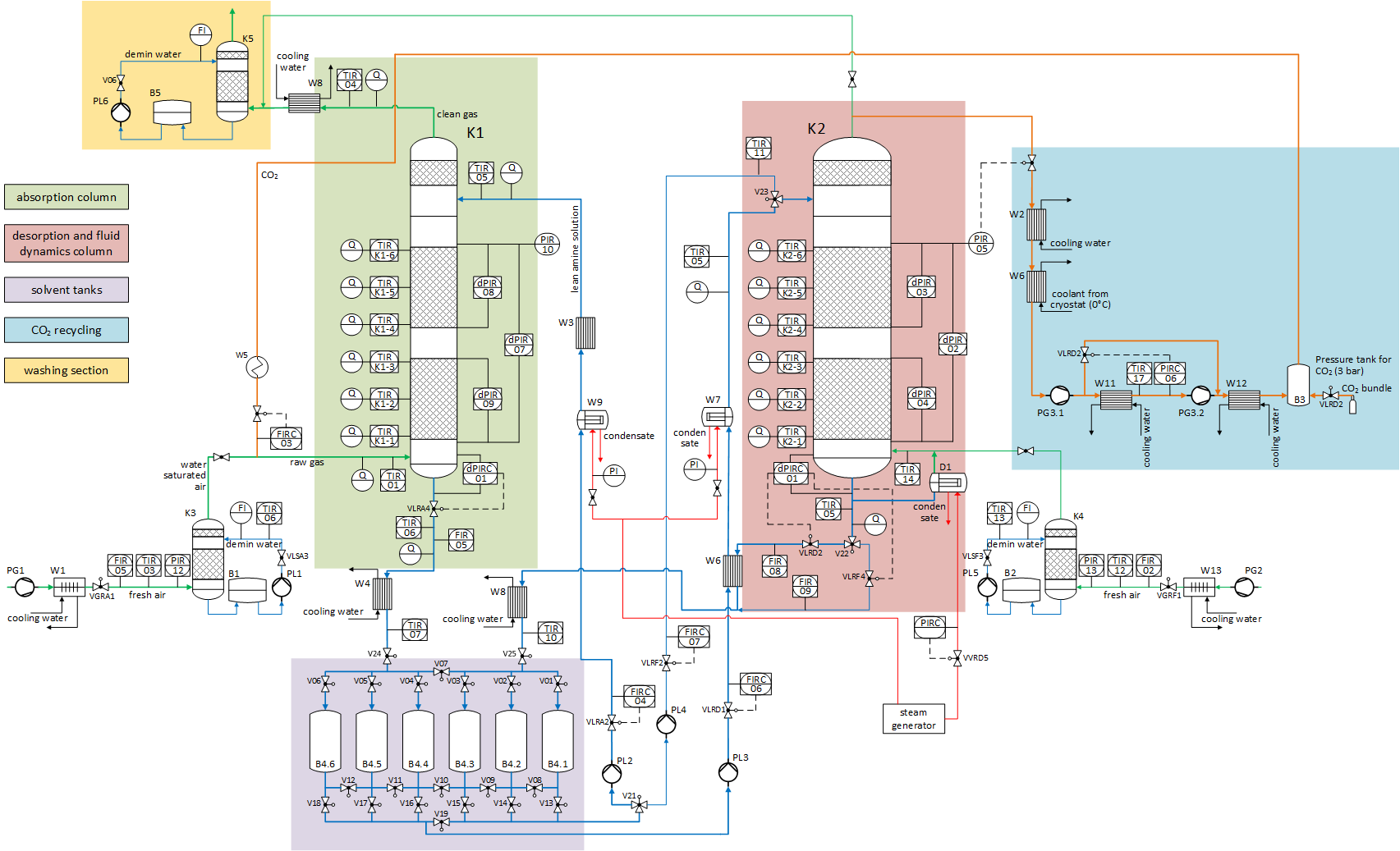

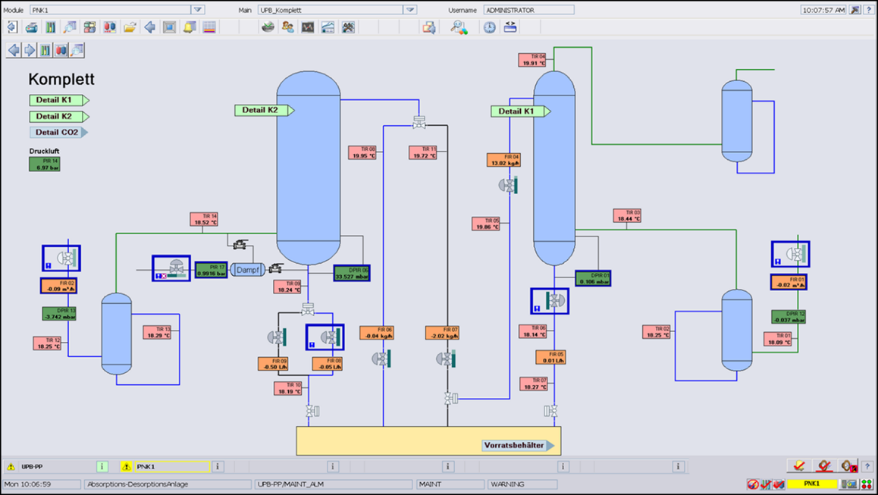

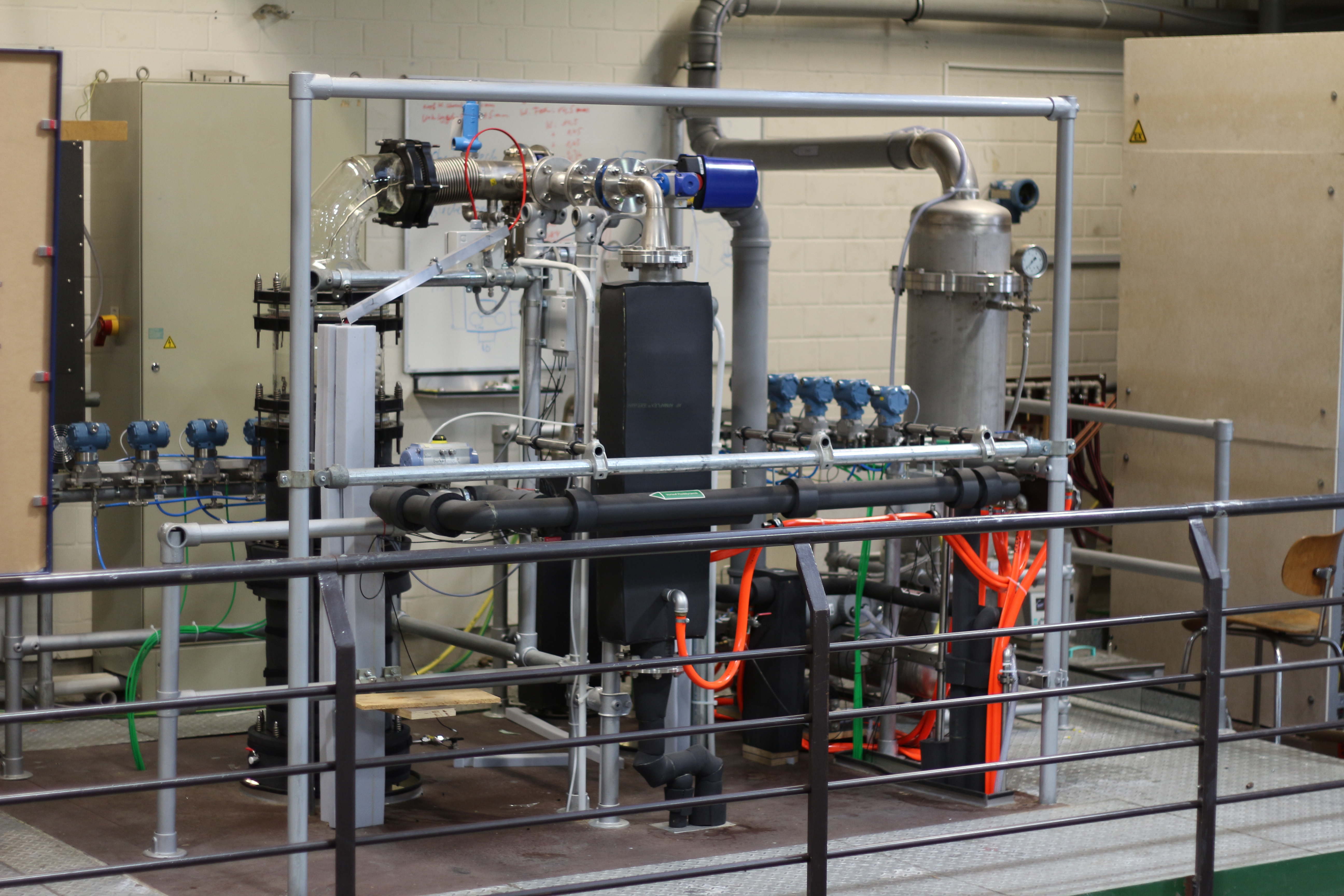

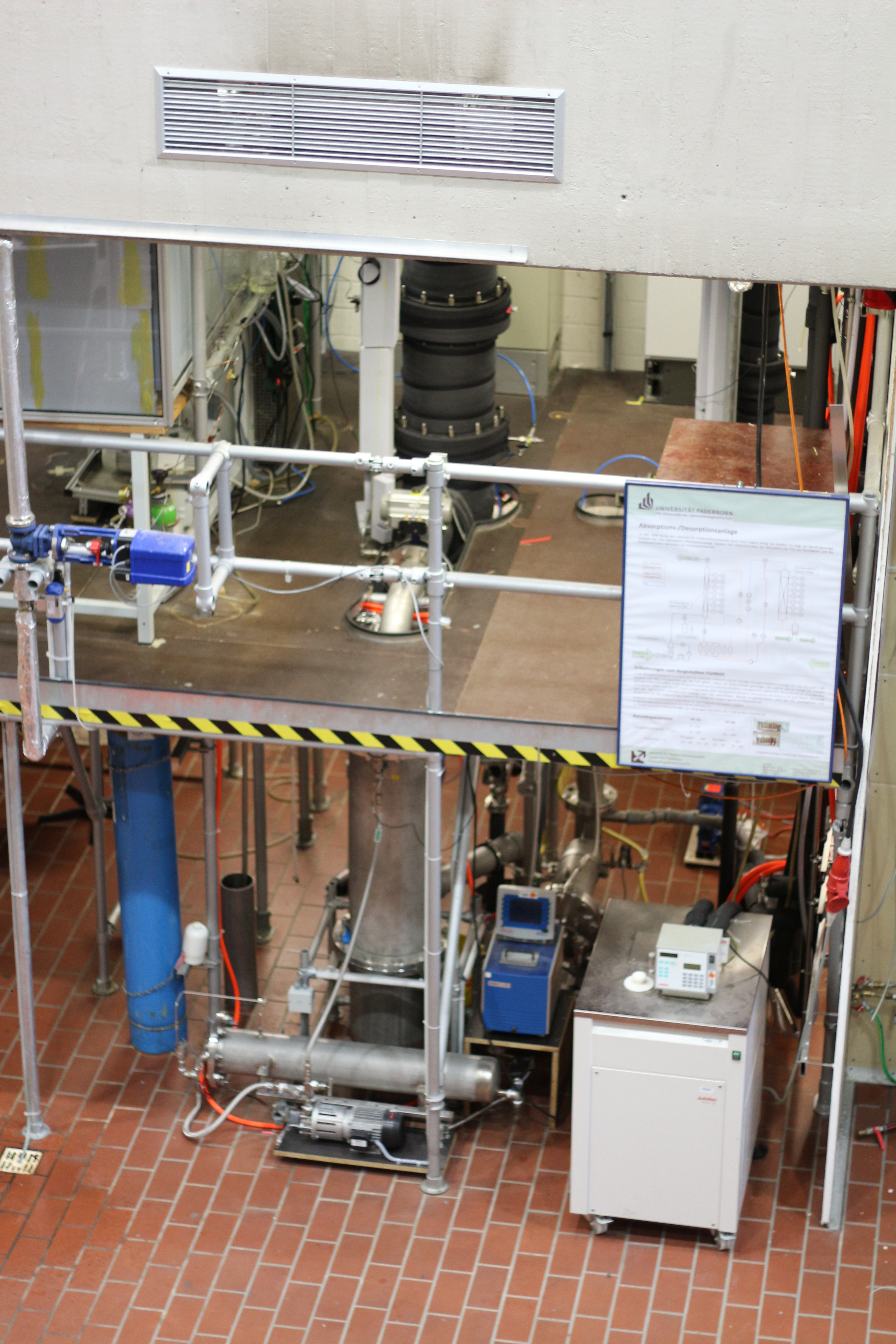

The recently built multi-purpose pilot plant can be used for fluid dynamic studies of packings and other internals as well as for absorption and desorption experiments.

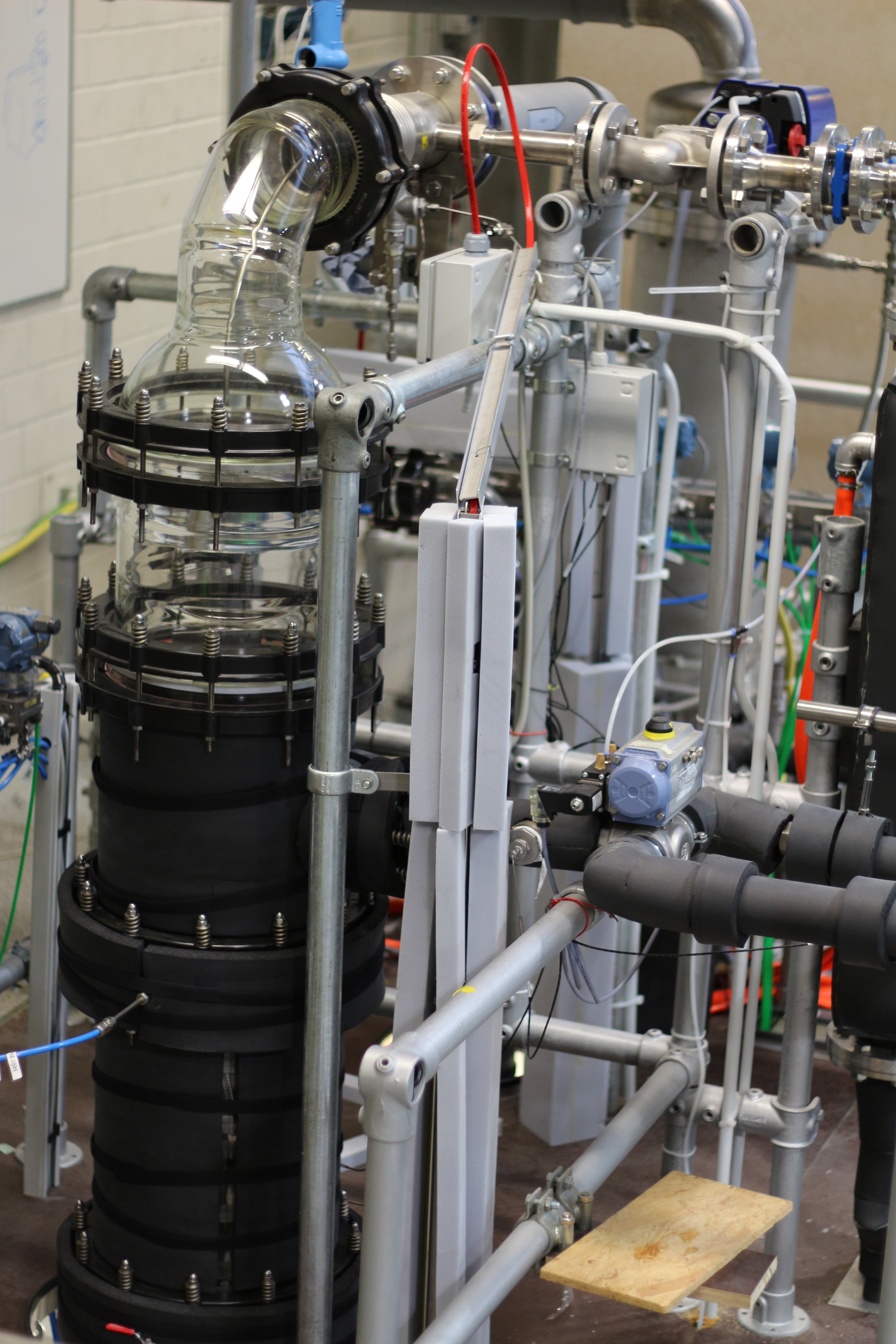

Set-up

- two glass columns:

- absorption column (K1 in the flow sheet): inner diameter of 100 mm

- desorption and fluid dynamics column (K2 in the flow sheet): inner diameter of 300 mm

- packing: Montz B1.250; packing height: 3 m each

- operation modes:

- absorption: only K1 is used

- closed loop: absorption in K1 and desorption in K2

- fluid dynamics: observations and pressure drop measurements at K2

Operating conditions

absorption, K1 |

fluid dynamics, K2 |

desorption, K2 | |

| F-factor liquid load liquid-phase temperature gas-phase temperature | 1 - 3,5 Pa0,5 10 - 60 m³/m²h 20 - 40 °C 20 - 60 °C | 1 - 4 Pa0,5 10 - 100 m³/m²h 20 - 40 °C 20 - 60 °C | 10 - 60 m³/m²h boiling temperature |

Sampling and analytics

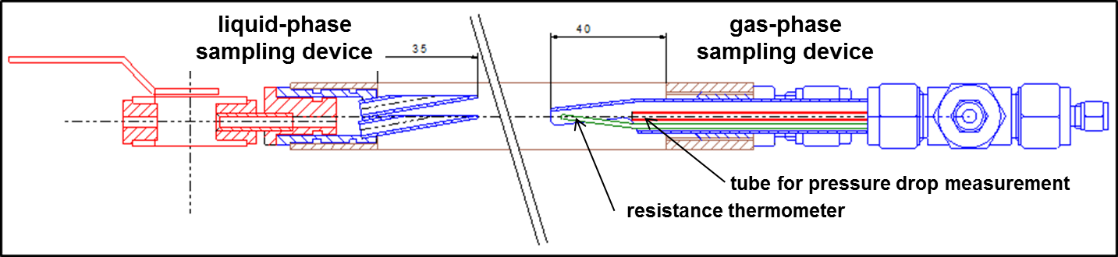

The two columns are designed to measure axial temperature and concentration profiles. Both gas-phase and liquid-phase samples are taken with the aid of specially developed sampling flanges placed at 0.5 m intervals along the packing height.

Liquid-phase sampling:

- Liquid trickles into the upper tube at the tip of the device, flows through the chamber and trickles out of the lower tube

- With a syringe, the liquid can be taken from the chamber; liquid samples are collected and analysed off-line

Gas-phase sampling:

- A tube is inserted into the flange and connected to the gas chromatograph via a system of heated pipes and a vacuum pump

- Gas-phase samples are analysed online