07-27-2013 | Brief report

KAt-Excursion 2013

On July 24th, 2013 the Chair of Design and Drive Engineering headed by Professer Zimmer went on a two-day excursion. The Chair, staff members, a number of student assistants and interested students started out on a tour to expand their knowledge in the field of drive engineering. Twenty-two participants visited the companies Siemens, Winergy and Vogelsang as well as the mining museum in Bochum.

In the morning of July 24th, the participants met at the University of Paderborn to take off towards Voerde, where the plant premises of Siemens, formerly Flender, and their subsidiary Winergy are located. Following a warm reception, the supervisors introduced the individual departments and their products. In Voerde, Siemens develops and produces components for mechanical and electrical engineering, incl. standard transmissions and couplings as well as application-specific transmissions. These are installed in numerous applications such as ships, power plants or mills for processing rocks. Standard transmissions are offered with a rotation moment (torque) ranging from 2,000 Nm to 2,600,000 Nm.

Winergy emerged from the wind energy business of the company Flender, offering transmissions, couplings and services for wind power plants. Winergy is market leader in this field, supplying manufacturers such as Vestas, General Electric or Nordex. Their various products cover a power output range from 0.7 MW to 6.5 MW.

Following some interesting insights into the product portfolio and innovative solutions and some refreshments, the participants started a tour of the factory buildings of both companies. The vertical transmissions implemented into cement mills were particularly impressive. They are 4m tall, weighing 100 tons each. Using modern machine tools enable the well-trained employees to obtain manufacturing tolerances of a few thousandths of a millimeter with unit weights of several tons. Each transmission is tested comprehensively prior to shipping, using one of several test benches in the factory. The largest test bench has a performance of 14 MW. At the end of the tour, there was sufficient time to answer unresolved questions.

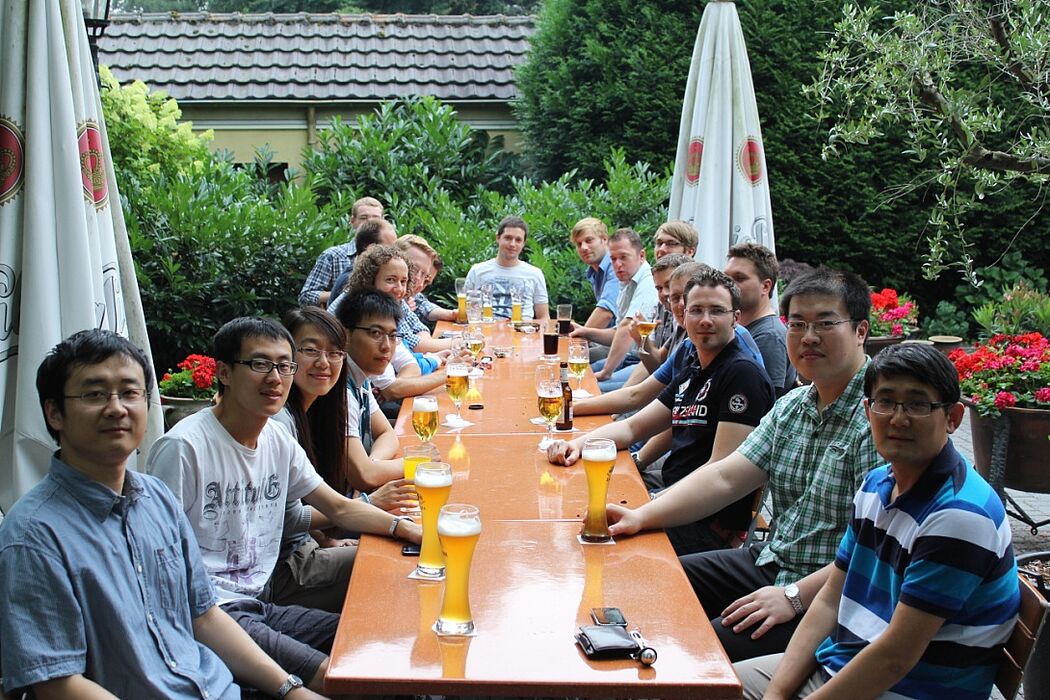

After this interesting day at Siemens, the group moved on to a hotel not far from Dinslaken. After a joint dinner, the evening was concluded in the beer garden of the hotel.

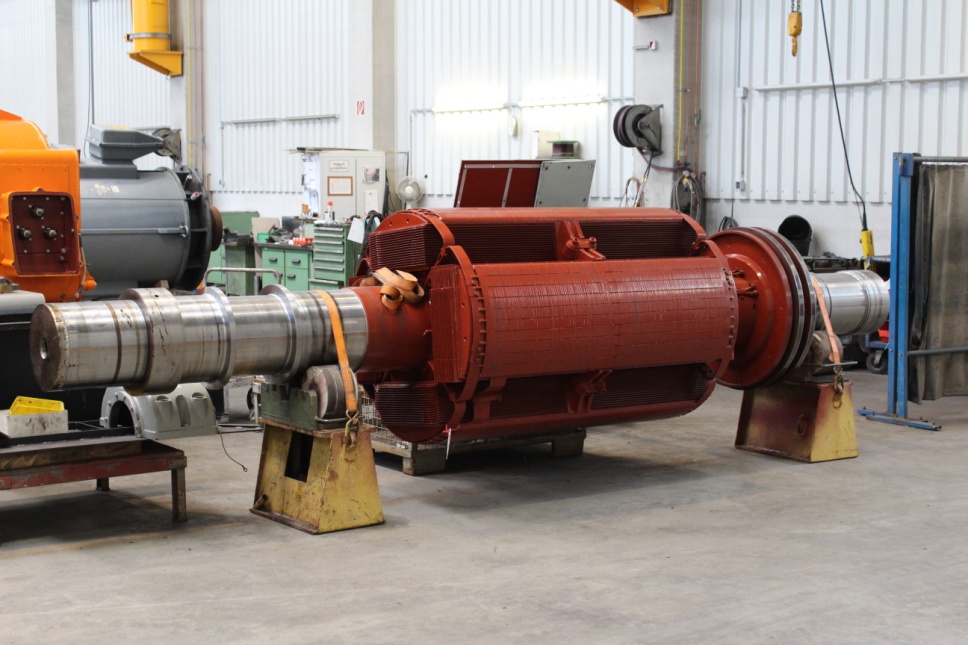

The next morning, the company Vogelsang in Bochum was visited. First, the owner himself provided an insight into the history and fields of activity of his family business, which is currently run by the fourth generation. Vogelsang services and repairs various components of drive technology such as electric motors, transformers or pumps. These components are exclusively custom-made or produced in small batches. High-volume products can be more easily replaced. By now, the company employs 200 persons at several locations in Germany as well as in neighboring countries. After a presentation of the company, the factory buildings were toured. During this tour, large electric motors could be examined, such as those employed in large rolling mills.

Vogelsang has several subsidiaries. One of them deals with an early diagnosis of damages to drive systems. Particularly methods of damage diagnosis and prevention in engineering plants were discussed with employees.

In the afternoon, the Mining Museum in Bochum was visited where work conditions and mining machinery could be examined. The view from atop the shaft tower (60 m), which - like the mining gallery - was constructed specifically for the museum, was impressive.

Back in Paderborn, the excursion concluded with a dinner in the Haxterpark, where a heavy downpour was unable to drown the positive impressions of the excursion. Fascinated by the new experiences some interesting points were discussed and unanswered questions settled.

Text: Thorsten Kossmann and Magnus Schadomsky

Photos: Johannes Tominski and Nils-Peter Kriegel