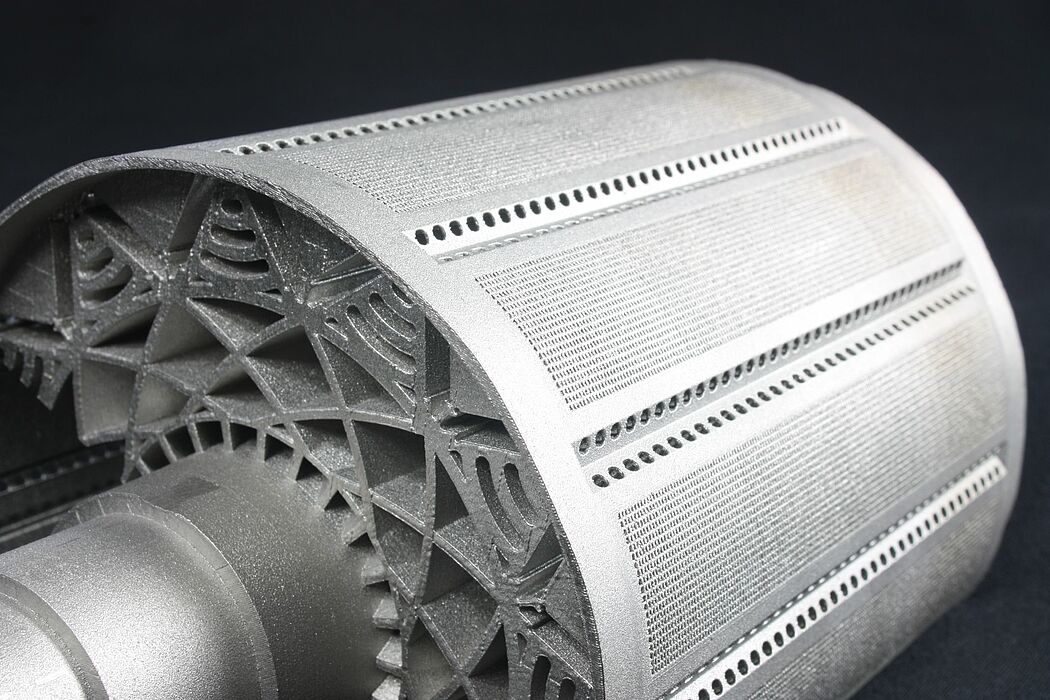

Laser beam melting (LBM) of ready for use parts of ferrosilicon alloys with a high silicon content is very promising and challenging at the same time. While significantly improving soft magnetic properties, a higher silicon content also promotes brittleness, making these alloys hardly suitable for the production of parts with a height of more than a few millimeters. To overcome these challenges, the potential of a building chamber preheating system implemented in a standard LBM machine is analyzed with regard to zero-defect and crack-free manufacturing of large-area samples and components made of brittle ferrosilicon alloys. In addition, this study also investigates the influence of the silicon content on the soft magnetic and mechanical properties of additively processed ferrosilicon alloys by processing four alloys with a silicon content between 2.4 % weight and 10.0 % weight into samples with different dimensions. The manufactured samples are then heat-treated and the resulting influence of both the silicon content and the heat treatment on the microstructure as well as the soft magnetic and mechanical properties analyzed. It has been shown independent of dimensions zero-defect and crack-free parts can be manufactured. The iron alloy with 6.7 % weight silicon has the best permeability, which can be improved by the factor 1.5 through suitable heat treatment. These results provide a basis for powder bed melting of application-adapted components with excellent soft magnetic properties which can hardly be produced by conventional technologies.

Publication in "Journal of Materials Processing Technology"