POLYLINE

Integrated line application of polymer-based AM technologies

Sponsor: Federal Ministry of Education and Research (BMBF)

Funding Program: Photonics Research Germany - Light with a Future; Funding Initiative "Line Integration of Additive Manufacturing Processes (LAF)

Project Management Agency: VDI Technologiezentrum GmbH (VDI-TZ)

Duration: 3 years

Description

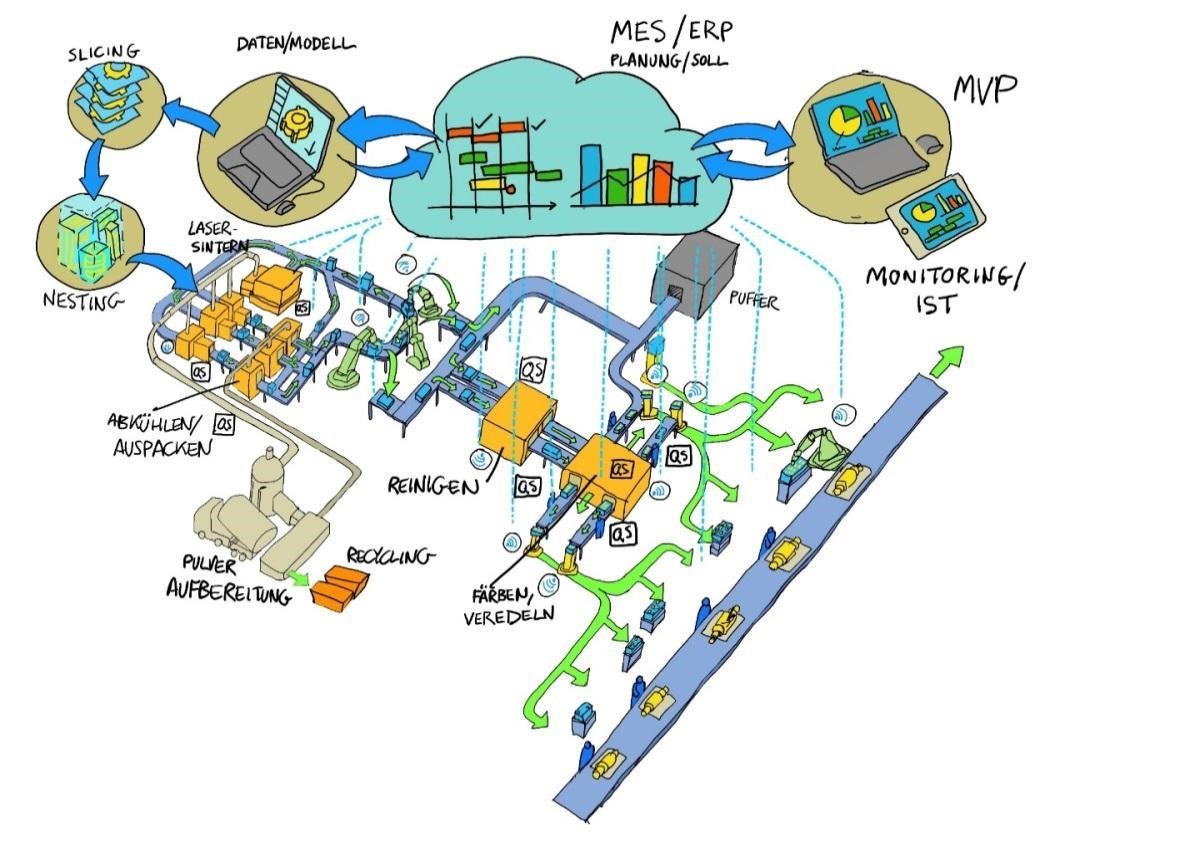

The aim of the POLYLINE project is to further develop additive manufacturing with polymer-based laser-sintering (LS) into an automated and efficient production process. The AM technology is to be enabled to meet classical processes (machining, casting, etc.) in high-throughput line production systems on an equal footing.

Objectives

Additive manufacturing can realize almost any geometry and even complex structures without significant additional effort - a big step towards mass production of individualized products. Currently, however, both vertical and horizontal integration of additive manufacturing processes in conventional lines is only feasible to a limited extent due to the lack of standards across process chains. This is due to AM-specific production steps (e.g. production time in the "batch process") and the generally low level of automation of the physical handling and transport processes. On the other hand, the digital data chain along the horizontal process chain is not continuous at many interfaces, which currently leads to intransparency, error-proneness and limited monitoring along the process chain and makes integration into relevant production control systems more difficult. These obstacles limit the obviously high potential of additive manufacturing processes in existing series production and assembly lines.

To achieve this project goal, the project aims at a digital and physical system breakthrough. This means that from the CAD model to the finished component, all central characteristic values and quality criteria (including marking, history and measured values) are recorded and documented. The individual sub-processes of production - from process preparation to the laser-sintering process, cooling and unpacking as well as cleaning and reworking of the parts - are automated and brought into the planned production line, where all trades of an LS production chain are fully linked for the first time. In the future, this will enable a more flexible production with parts manufacturing directly in Germany, which will be demonstrated by the example of series parts from the automotive industry.

Research at C.I.K.

In POLYLINE, the C.I.K. department, together with other research partners of the project, is working on the horizontal process chain for the integration of additive manufacturing into a line process. The focus is on the development of a holistic concept for additive manufacturing, including the consideration of quality management. With the DMRC (Direct Manufacturing Research Center), the University of Paderborn has a high level of expertise in the field of AM and can draw on the experience of several national and international research projects.

Related Links:

https://www.photonikforschung.de/projekte/photonische-prozessketten/projekt/polyline.html