Digital Image Correlation

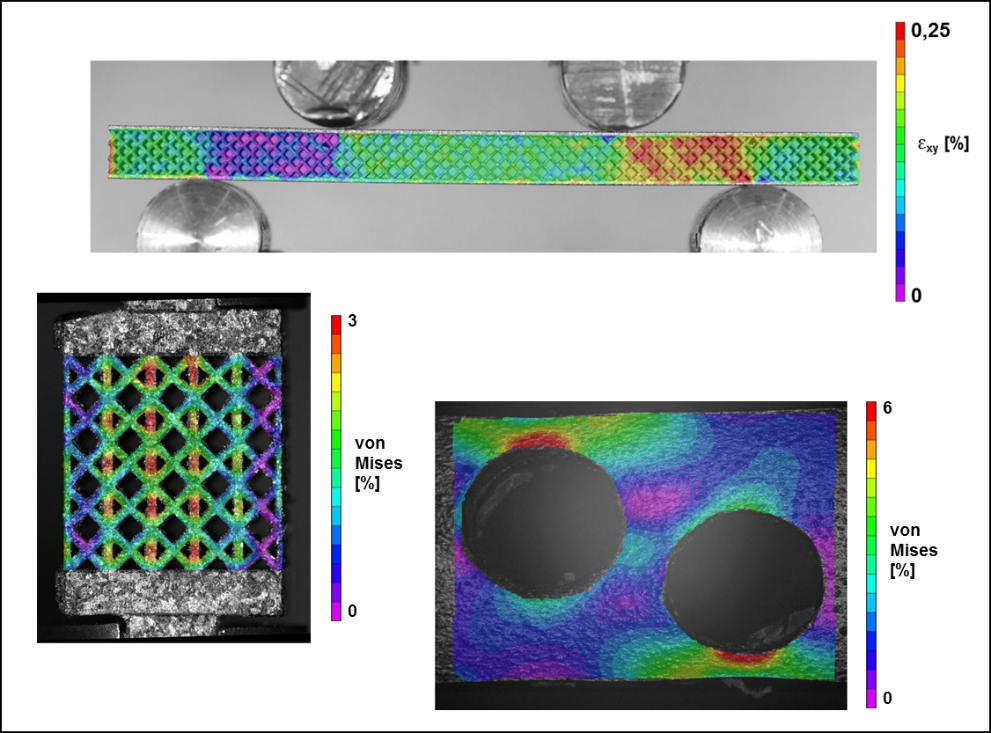

Digital Image Correlation (DIC) technology enables researchers to determine local strains, and thus the locally occurring stresses, in a component under loading. The technology is based on an optical process in which images are taken of a specimen surface in its initial condition, as well as at multiple stages during and/or after deformation. The strain distribution can then be calculated based on the displacement of individual “speckle” points/patterns on the surface of the part. Similar to Finite Element Analysis (FEA), the visualization of the strain distribution is color-coded, allowing areas affected by design or material-related defects to be identified easily and intuitively. In addition, conclusions about deformation due to micro-structural factors can also be drawn based on the results. Depending on the depth of resolution required, various optical imaging techniques can be used.

Optical Imaging Techniques

- DSLF Nikon D3200

- Digital (optical) microscope

- Confocal microscope

- Scanning electron microscope

Applications

DIC can be used in combination with the majority of the testing equipment available at the LWK, offering a method of generating visualizations of specimen loading under varying load conditions. The following list gives possible examples of applications where DIC could be incorporated:

- Visualization of crack propagation under cyclical load (fracture mechanics)

- Load distribution in complex light-weight structures

- Early damage detection under cyclical load

- Examination of matrix/fiber bond quality in compound materials under load

- Visualization of stress-induced phase transformation

- Detection of microstructural inhomogeneities