Team Materials & Processes

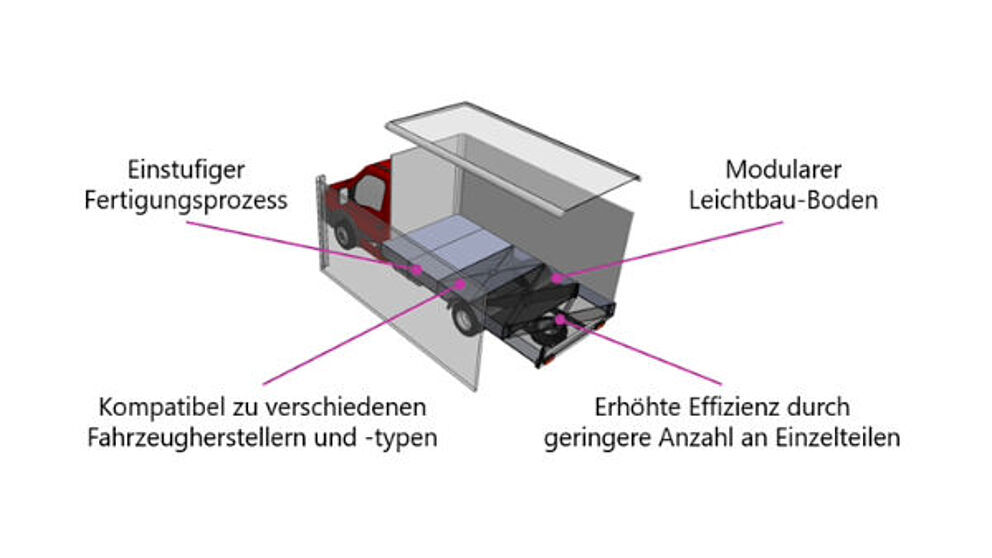

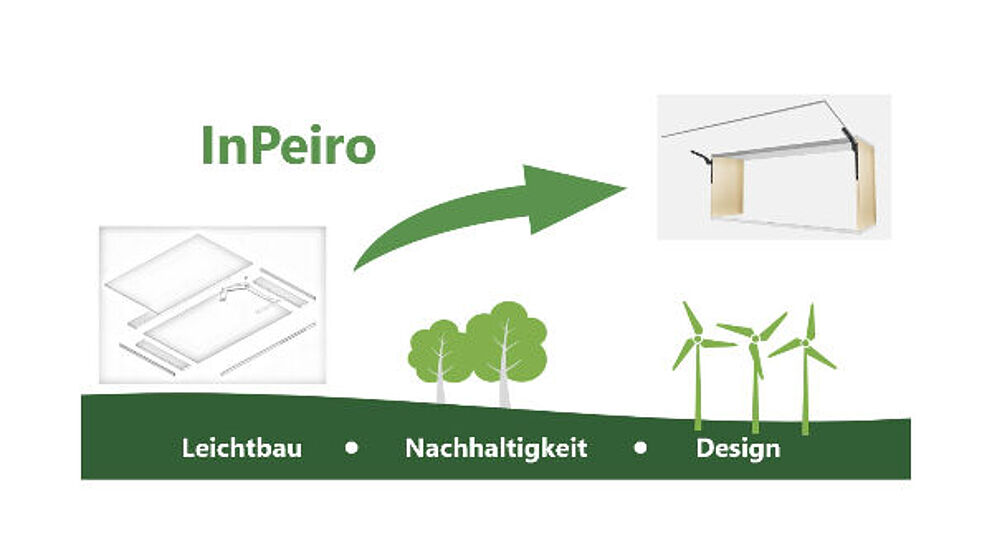

The Materials and Processes team focuses on processing materials with high potential for lightweight applications. This potential is defined by maximizing the ratio of strength or stiffness to density. Therefore, high strength steel, aluminum, and titanium alloys as well as fiber reinforced plastics are of interest. Depending on the application, it may also be beneficial to combine different materials. Such hybrid combinations take advantage of the strengths of each material and reduce their individual weaknesses.

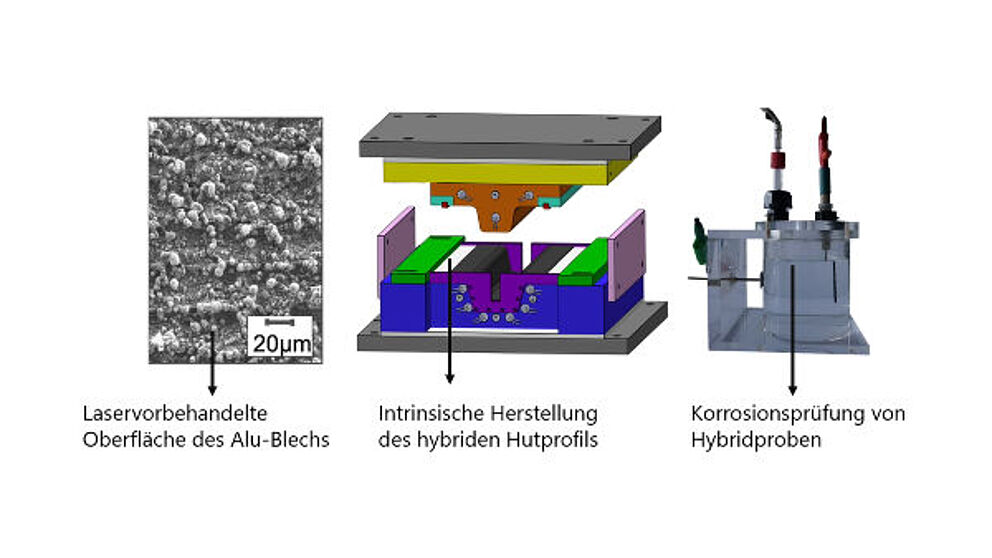

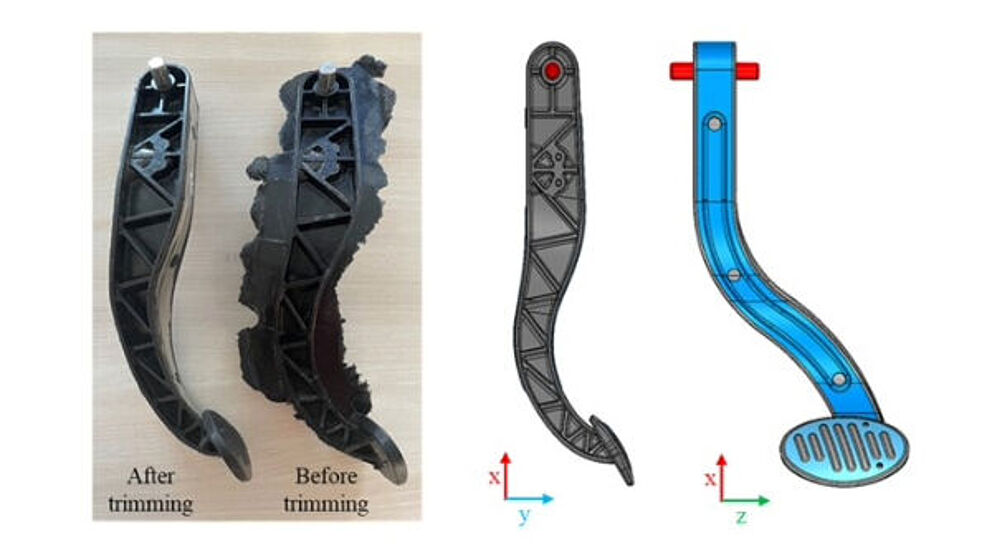

The analysis of production processes aims not only to improve the mechanical properties of the materials, whether individual or combined, but also to ensure energy efficient and resource saving processing. This includes specific heating techniques such as induction and conduction, or combined process steps such as in-mold assembly. These optimizations are first tested on small-scale samples and later transferred to full-size demonstrator components. Process research is supported by numerical methods such as forming simulations and filling studies. Validation of process results is done through image-based evaluation at both micro and macro levels as well as mechanical testing.