Team Simulation & Method Development

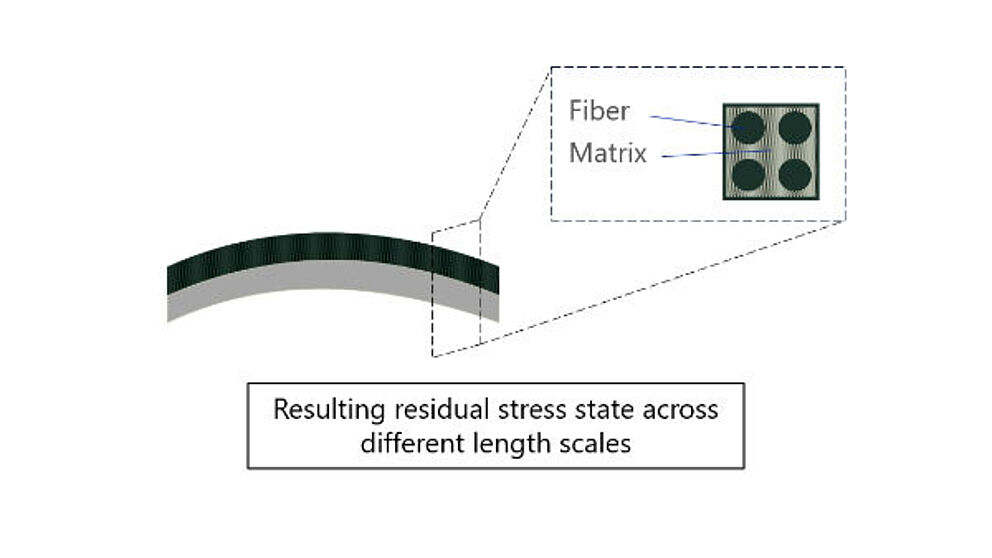

The Simulation and Method Development team works on the modeling and analysis of mechanical systems, their manufacturing processes, and the evaluation of environmental impact. Depending on the level of detail, simulations are performed at the micro or macro mechanical level. For a reliable understanding of the mechanical behavior of a component concept, the focus is on the accurate definition of boundary conditions and the development of material models. This enables simulations that reflect realistic loading conditions and identify the interactions occurring in actual use cases.

To develop material models, the mechanical properties of materials such as aluminum, high strength steels, wood, carbon fiber reinforced plastics, and glass fiber reinforced plastics are characterized through experiments on the testing equipment available at the department.

The simulation methods include static implicit simulations of individual parts, modules, or complete structures. They also include explicit simulations for crash analysis, which are essential in automotive engineering. These allow prediction of stress and strain distributions within the component up to the point of failure. In parallel, the team develops and tests algorithms for damage and failure modeling. These are used to predict the initiation and progression of material damage in components and can estimate the residual strength of parts.

Another focus area in simulation is the analysis and design of joining technologies, both mechanical and adhesive, as well as the related manufacturing processes. This is important for evaluating the performance of assemblies and full vehicle structures, especially when the production method directly affects the final material properties, such as microstructure changes or strain hardening in metals during forming processes.

Validation of the simulation models is done through detailed comparisons between simulation and experimental results to ensure that the findings are accurate and applicable.

In addition to functional design and development, the team also conducts environmental impact assessments of lightweight solutions, for example through life cycle analysis. The aim is to evaluate the environmental effects of different concepts early in the development process to support material and process selection. This contributes to the development of lightweight designs that meet technical, economic, and environmental requirements.

Laufende Forschungsprojekte

Ausgeschriebene Arbeiten

Im Team Simulation und Methodenentwicklung beschäftigen wir uns Schwerpunktmäßig mit der Methodenentwicklung zur Potentialfindung und Optimierung von hybriden Werkstoffverbunden. Ein besonderer Fokus liegt in der Materialmodellierung von Werkstoffen und deren experimentelle Kalibrierung. Die Materialmodelle werden beginnend von der Prozesssimulation bis hin zur Komponenten- und Gesamtfahrzeugsimulation benötigt. Um die lebenszyklusübergreifenden Umweltwirkungen von Leichtbaustrukturen zu minimieren, liegt ein weiterer Forschungsschwerpunkt im Bereich der Methodenentwicklung zur Integration von Ökobilanzierungen (englisch: Life Cycle Assessments) in den Entwicklungs- und Auslegungsprozess.

Online-Bewerbung LiA

Für die unkomplizierte administrative Betreuung der Arbeit nutzt der Lehrstuhl ein Online-Bewerbungstool. Hier können alle wesentlichen Daten hinterlegt werden. Bitte nutze dieses Tool (Online-Bewerbung LiA). Anhänge wie Lebenslauf und aktueller Notenspiegel sind im Tool per Anhang hochzuladen.

Für Arbeiten, die in Kooperation mit einem Industrieunternehmen angefertigt werden sollen, ist zusätzlich ein Exposé zum gewünschten Thema der Arbeit beizufügen.