Rheology of Suspension

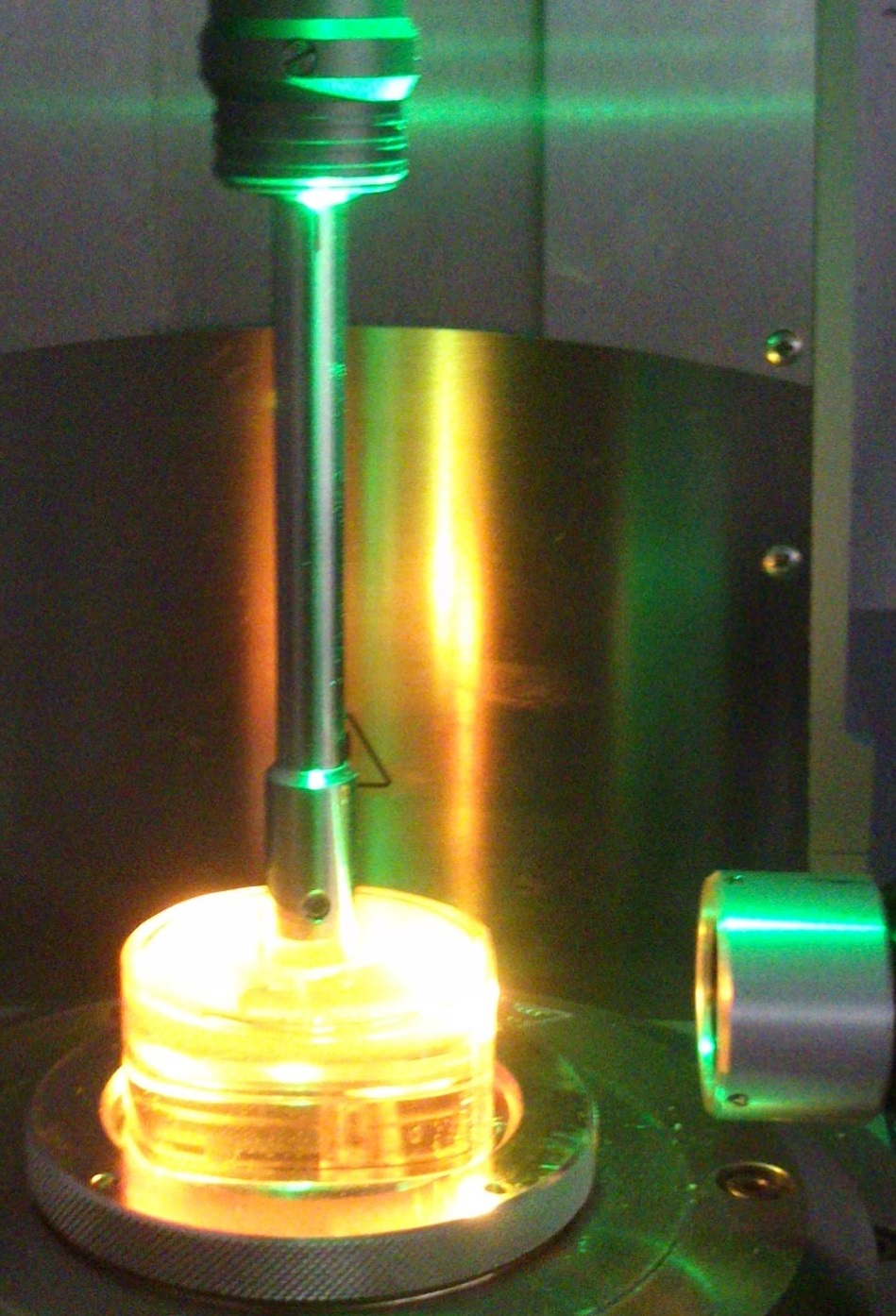

Rheology is fundamentally concerned with the deformation of matter in both the solid and liquid state. Both single-phase materials and multiphase systems are investigated with regard to different parameters such as load and time behavior. Suspension rheology represents a subarea of this field. The flow properties depend on a variety of particulate properties such as shape, size, size distribution and interaction as well as the suspension matrix. In particular, with respect to shear rate dependence, suspensions exhibit extremely diverse flow properties such as apparent wall sliding. Another field of research, less studied for technical reasons, is extensional rheology (single-phase material and multiphase system), which is of great importance especially in plastics processing. At the Chair of Particle Process Engineering a wide range of different measuring systems is available for research in the field of rheology. Currently, the work is concentrated on the characterization of complex colloidal systems (suspensions) as well as extensional rheological investigations of polymer melts. Conclusions are to be drawn from this for the modeling of the various processes.