High power ultrasonic bonding in energy-efficient power semiconductor modules

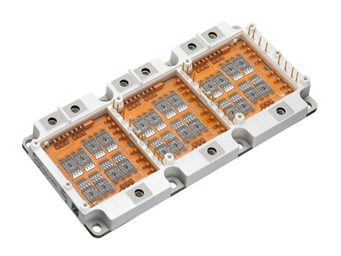

The increasing current density in future power semiconductor chips requires an increase in the electrical cable cross section within power modules. The chips are electrically contacted by the so-called "ultrasonic wire bonding". This manufacturing process was developed as part of the project "High power ultrasonic bonding in energy-efficient power semiconductor modules" funded by EFRE.NRW within the lead market competition Production.NRW in a cooperation between Hesse GmbH (Paderborn), Infineon Technologies AG (Warstein) and the Chair for Dynamics and Mechatronics of Paderborn University from 1.4.2016 to 31.3.2019.

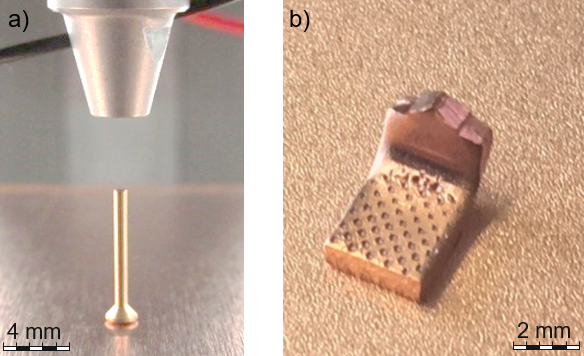

A newly designed vibrating system was set up which, thanks to multi-dimensional, multi-frequency excitation, provides sufficient ultrasound power to reliably connect semi-finished copper products with a larger cross-section (up to 3 mm2 instead of 0.3 mm2). The necessary ultrasound power (up to 300 W) is brought into the connection point gently and efficiently without causing damage. It has also succeeded in substituting the soldering process when setting plugs in power semiconductor modules. As a result, the efficiency of power semiconductor modules can be increased further in the future and thus contribute to a more efficient energy supply.

This project was funded by the European Regional Development Fund (ERDF). The publications created as part of the project can be found here.