Modeling the Heavy Wire Bonding Process

Due to the sometimes very high time and associated costs for the experimental optimization of the wire bonding process, simulation is an important component as a development tool in the design of new wire bonding processes. In addition, despite the short process times, the small dimensions of the bonding tool and the wire, a deep insight into the process sequences is possible with models. Based on the models developed at the chair, a model-based optimization of the process parameters can be performed.

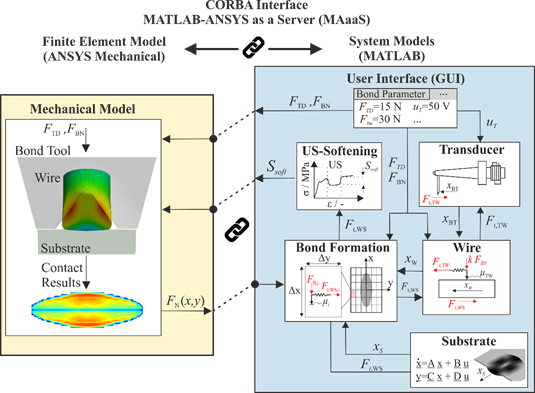

Within the framework of the project "InCuB" within the BMBF-funded top cluster "it's owl", a model was developed which comprehensively depicts the bonding process in its most important components. This model is continuously being developed further in current work at the chair. An approach of co-simulation between MATLAB and ANSYS is pursued. This model includes an integrated finite element model, which calculates the current wire deformation and transfers the contact results to the MATLAB simulation. The wire deformation model, which was previously based on machine learning, is replaced by a physically based material model based on experimental investigations. In order to be able to analyze the experimentally observed influence of the substrate dynamics on the bonding result, the dynamic models in MATLAB were extended by a substrate model.