Powder Manipulation

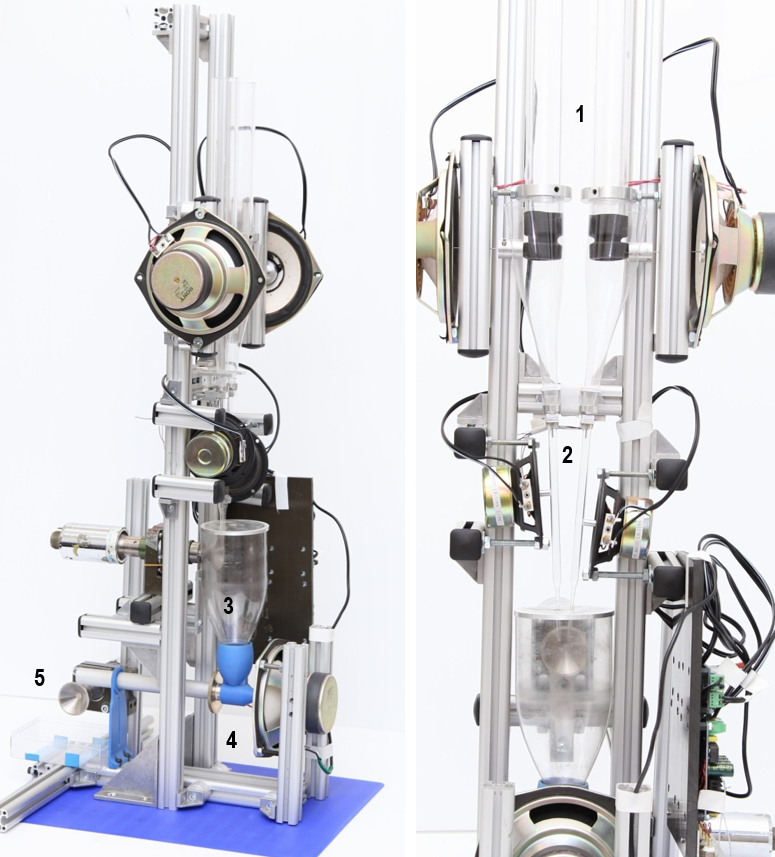

The object of this ZIM-funded project (KF2363847WO4), which was carried out together with Athena Technologie Beratung GmbH, was the development of a modularly designed overall concept for a fine powder manipulator for dry fine powders with storage container incl. extraction module, dosing unit, transport system, homogenization unit and dispersion module which enables the user an uncomplicated, process-adapted powder extraction, dosing, component mixing, homogenization and dispersion. In order to achieve these goals, high-frequency vibrations (ultrasonic technology) should be used above all.

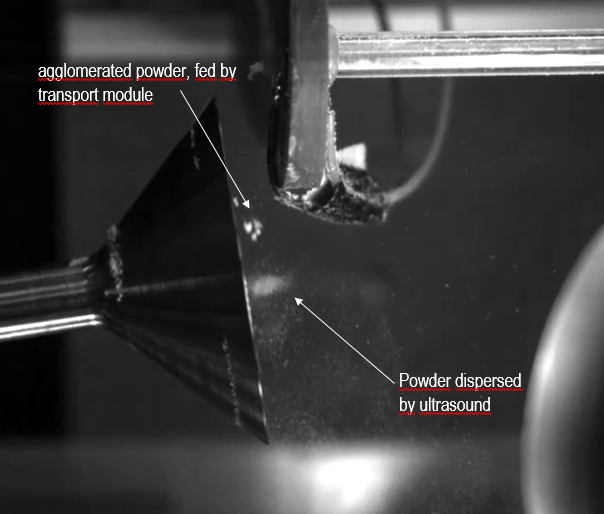

In the processing of ultra-fine powders with particle sizes of approx. 1 to 100 µm, the strong agglomeration (formation of particle lumps) in particular causes problems in dosing (bridging, clogging), mixing (inhomogeneous mixture due to agglomerates) and transport (increased friction). Low-frequency vibrations were used for powder extraction and dosing, which fluidize the agglomerated powder and thus allow it to flow through a sieve or a narrow hopper. Ultrasonic acoustic vibrations were used in both the homogenization unit and the dispersion module to atomize the highly agglomerated powder into individual particles (see Figure 1). In the homogenization unit a homogeneous powder mixture was produced from atomized powders. The application of acoustic ultrasonic vibrations delivered absolutely satisfactory results when using flour, cocoa and other similar powders as test powders. In the transport module a combination of low-frequency vibration for propulsion and high-frequency vibration for friction reduction was used. Further research results on powder transport with ultrasound can be found under the following link: Ultrasonic Powder Transport.

As a result of the project, a modular system was developed with which ultra-fine powder can be dosed, mixed, transported and finally finely atomized. This system is shown in figure 2.

Publications of the chair on this research topic here.