Ultrasonic Heavy Wire Bonding

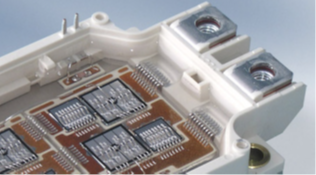

Ultrasonic heavy wire bonding is an interconnection technique used in the semiconductor industry. Here, wires with a diameter of 75 μm up to 600 μm are used, for example to connect IGBT chips in high-performance modules. Such modules are used in traction power supply systems, industrial electric drives, electric cars and in the field of renewable energies in wind power and solar plants.

The bonding process is divided into four bonding phases: the pre-deformation of the wire by the "touchdown force", the cleaning of the joining zone by the ultrasonic excitation with the bonding tool, the deformation of the wire by the action of the ultrasound ("Ultrasonic Softening" effect) and the interdiffusion between wire and substrate by the approach of the faying surfaces as well as plastic flow of the materials. Without the additional introduction of heat, a material bond is created between the wire and substrate. Ultrasonic heavy wire bonding is therefore suitable for joining different types of metals without thermal stress on surrounding components.

Many impact factors, such as the ultrasonic amplitude, the excitation frequency, the normal forces and the duration of the ultrasonic superposition have a great influence on the resulting bond quality; in most cases, this is determined by destructive test methods (shear or pull tests) and specified as the bond strength. The interaction between these parameters is highly complex and has not yet been conclusively researched. Therefore, experimental investigations and the simulation of the bonding process are core topics of current research and development in ultrasonic thick wire bonding in order to develop and optimize new processes with larger wire diameters and new material combinations; this also includes the development of new technologies such as multi-dimensional bonding and the geometry optimization of bonding tools.

Publications of the chair on this research area can be found here.