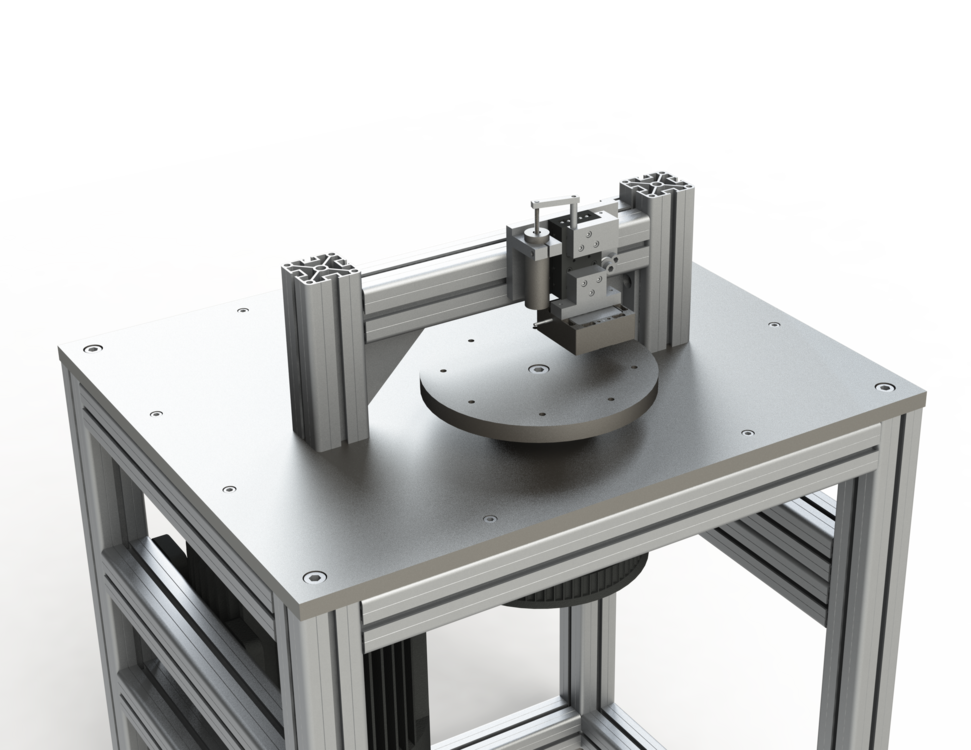

Tribometer

A tribometer enables to measure friction forces and hence to calculate coefficients of friction of various material pairings. The chair’s tribometer is operating under the pin-on-disk principle. A relatively small material sample is pressed onto a rotating disk. The sample geometry can be varied. Likewise, different friction surfaces can be applied to the disk. The acting normal force and the resulting friction forces are measured by a 3D force sensor. Finally, the occurring wear is recorded by a position sensor.

The tribometer allows the user to adjust the acting normal force. The relative speed between sample and disk surface can be controlled in a wide range. By variation of both quantities, so-called friction maps can be generated. These describe the dependence of the coefficient of friction, which is often assumed to be constant, on the normal force and the sliding speed. Especially elastomers, such as tire rubber, show characteristics with distinct maxima. The results enable the development and validation of complex friction and wear models.