Ultrasonic Systems and Processes

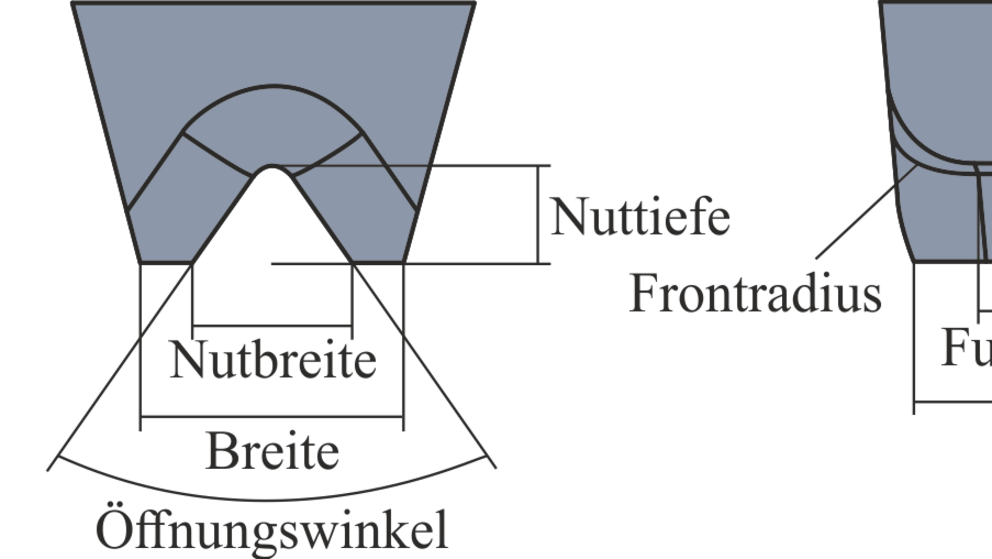

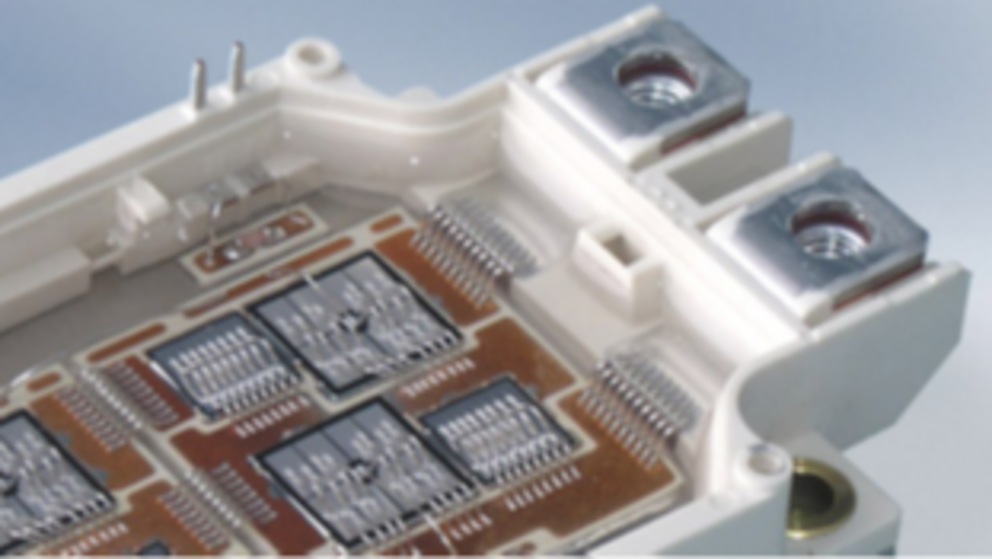

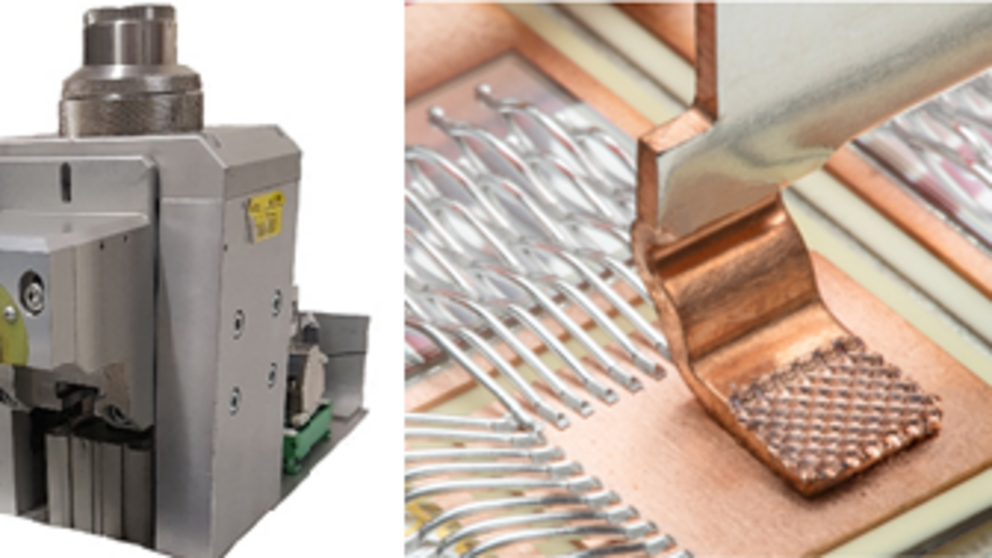

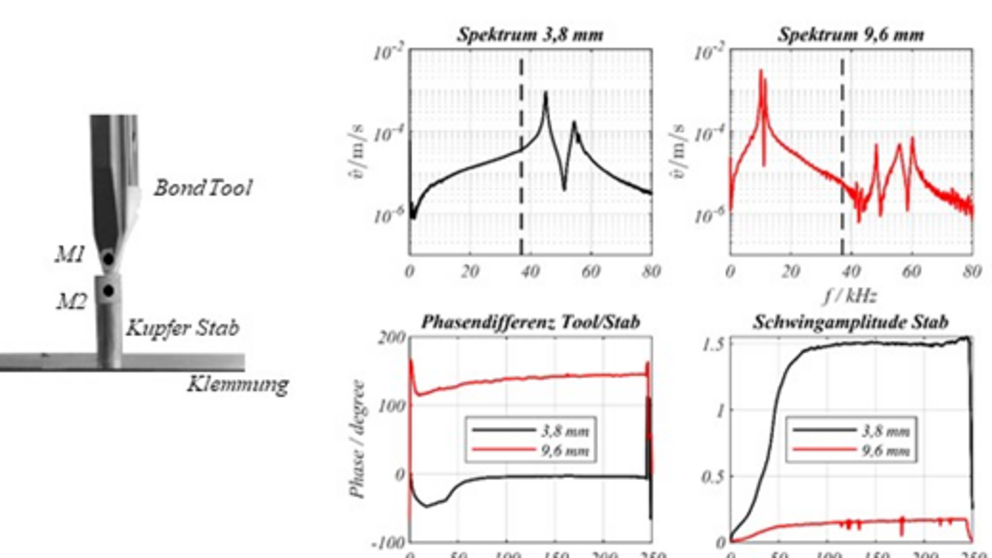

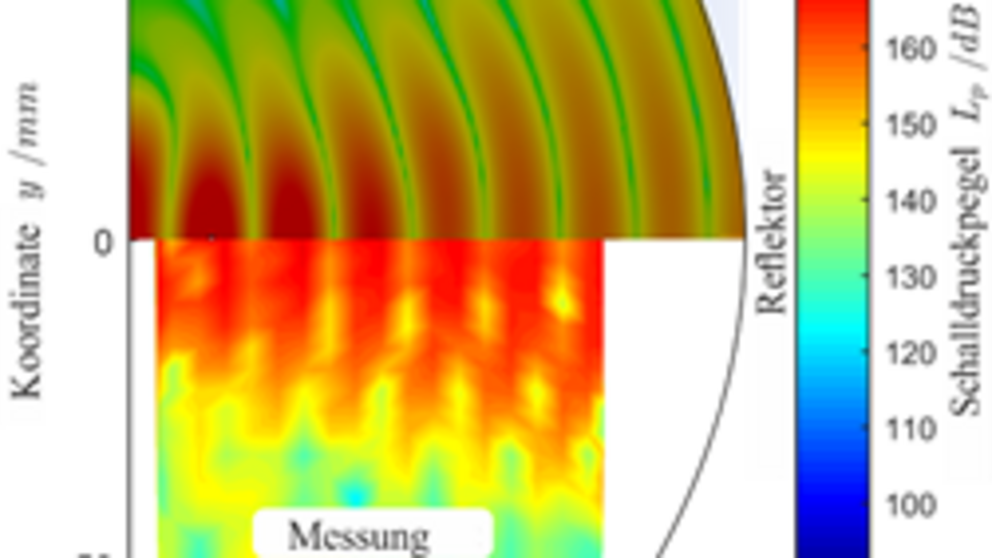

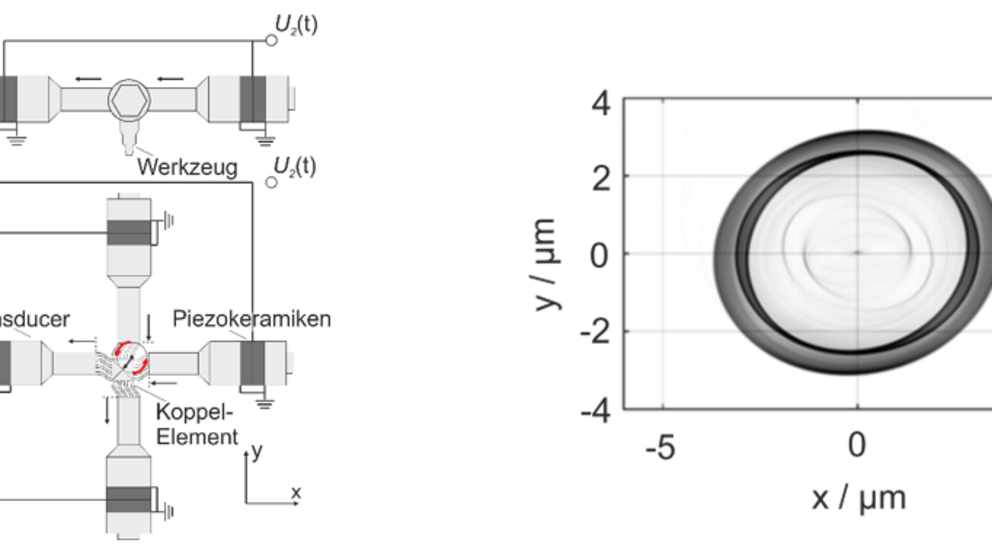

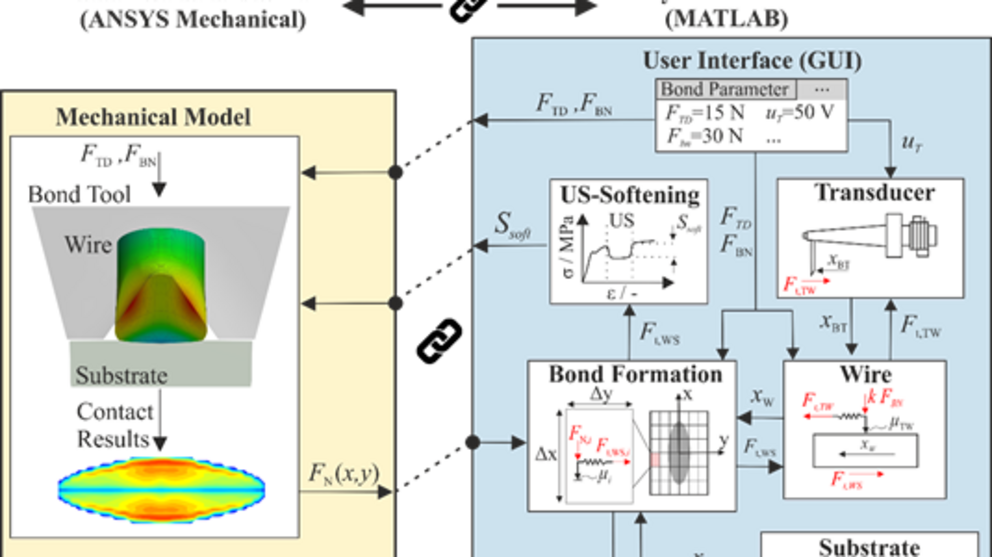

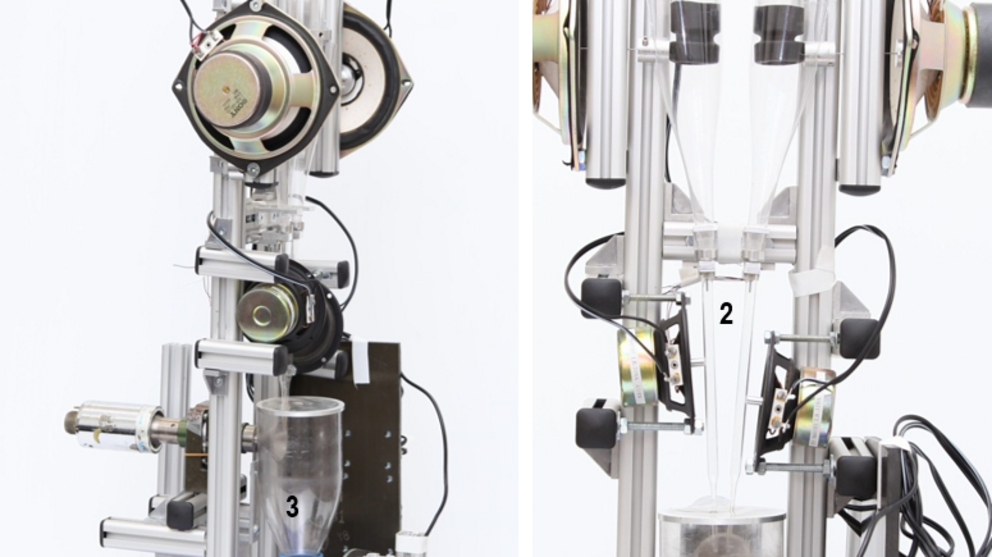

Ultrasound is used in a wide variety of areas of technology. Our focus is currently in the field of power ultrasound in actuator technology. High-frequency mechanical oscillations with low amplitude (< 100 µm) and high frequency (> 20 kHz) generate large velocities, sound pressures and accelerations, which can be transmitted to various fluids and solids and often can hardly be achieved by other technologies. Applications such as cleaning, machining and bonding have been in industrial use for decades. Nevertheless, there is a need for research, as many of the known processes have been developed empirically based on existing ultrasonic systems. With modern models, calculation methods and further developed control technologies, efficiency and performance can be increased and thus optimized systems can be built and new applications opened up.

Publications of the chair for this research area can be found here.

Current projects

Completed projects

Dr.-Ing. Tobias Hemsel

Faculty of Mechanical Engineering » Dynamics and Mechatronics (LDM)

Pohlweg 47-49

33098 Paderborn

Office hours

by appointment