manufacturing process and for the virtual load test of rupture discs

Overview

To minimise production line downtimes and the associated economic damage, maintenance, care and protection of the machines are essential. Rupture discs are used to protect pressurised systems that operate within defined limits.

Rupture discs are predetermined breaking points in the system so that excess pressure can be dissipated in a defined manner. The conventional production of these bursting discs is quasi-static without the use of numerical methods.

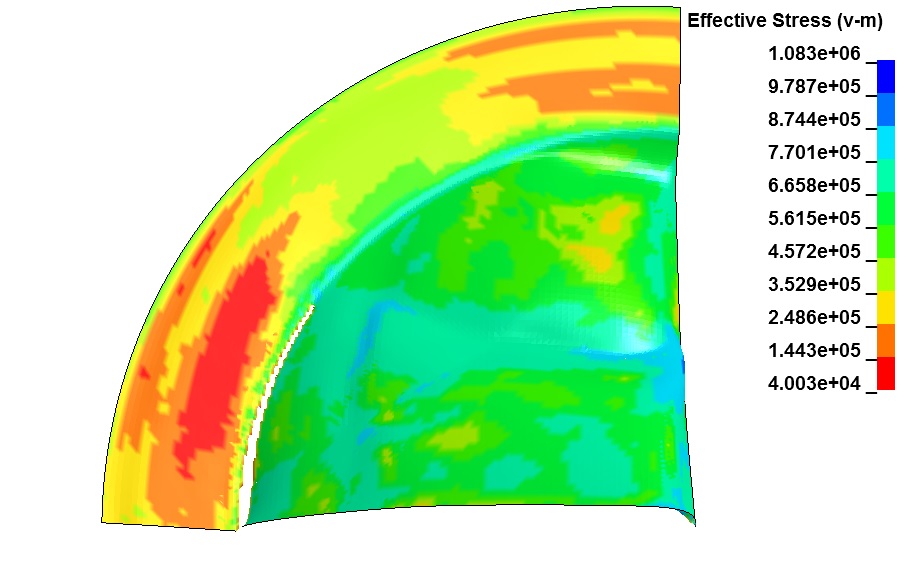

As part of the research project, the production of bursting discs using electromagnetic high-speed forming is being investigated. For this purpose, the forming process is modelled and optimised in a coupled FE simulation.

In particular, the effects of the different manufacturing processes on the bursting behaviour are being investigated. The increased forming limits due to high-speed forming are of central importance here. The use of secondary mould elements for the controlled failure of the bursting discs is another aspect that is considered in this investigation.

Funding organisations

The project is sponsored by the Federal Ministry for Economic Affairs and Energy and the Central Innovation Programme for SMEs (ZIM).