Electro-hydraulic high-speed forming

Overview

Electrohydraulic high-speed forming is one of the most promising innovative forming processes of our time. Due to the special process characteristics (high forming speed of 40µs to 2ms, very high peak pressures in the GPa field), the deformation of many materials can be significantly increased and thus sharp-edged or very fine geometries can be introduced into the material, which are very difficult or impossible to produce conventionally. Studies have shown that even radii below the initial sheet thickness can be achieved. High-speed forming is therefore particularly suitable for forming sharp-edged and/or very fine geometries that can also be formed locally. Due to its low space and energy requirements, electro-hydraulic high-speed forming is particularly efficient and, thanks to its high flexibility, can also be used very well as a process to support conventional forming.

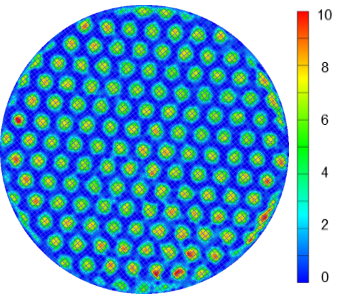

The electro-hydraulic forming process is dependent on a large number of process parameters. The influence of the individual parameters on the forming result has not yet been sufficiently investigated. The LUF is endeavouring to investigate the influence of different parameters such as wire, active medium, energy, etc. on the forming result in sheet metal forming through targeted investigations. Particular attention is paid to the pressure distribution on a sheet metal, which is one of the most important challenges. The fundamental aim is to prepare the electrohydraulic forming process for effective and profitable use in industry.