Forming machines

| Manufacturer: |

| |||

| Speed (max.): | 3000 rpm | |||

| Drive power: | 50 kW per axis (synchronous) | |||

| Compression force (support): | 50 kN per axis | |||

| Traverse path (support): | 450 mm (x-axis), 350 mm (y-axis) | |||

| Control/ regulation: | Siemens S7-d840 | |||

| Additional drives: | Geared motors | |||

| Power (additional drives): | 35 kW / 600 Nm each | |||

| Robot: | IRB 7600 x 2 |

| Manufacturer: |

| ||||

| Spindle speed (max): | 700 rpm | ||||

| Feed rate (max) : | 5000 mm/min | ||||

| Drive power (spindle): | 70 kW | ||||

| Drive power (roller infeed x): | 8.8 kW | ||||

| Drive power (roller infeed y): | 19.8 kW | ||||

| Tailstock pressure (max): | 210 bar | ||||

| Control system: | Siemens S7-300 / SINUMERIK 840D | ||||

| Axis control: | 4-X CNC (3 x-axes, 1 z-axis) |

| Manufacturer: |

| |||

| Speed (max): | 970 rpm | |||

| Drive power: | 11 kW | |||

| Drive (hydraulic): | 15 kW | |||

| Operating pressure: | 100 bar | |||

| Compression force (quill): | 60 kN | |||

| Travelling distance (quill): | 550 mm | |||

| Compression force (sleeve): | 40 kN per axis | |||

| Travel (support): | 450 mm (x-axis), 220 mm (y-axis) | |||

| Control/regulation | LabView - CompactRIO 9074 | |||

| Displacement sensors: | MTS-Tempsonic (Ethercat) |

Testing equipment - Mechanical testing

| Manufacturer: | Schenck-Trebel |

| Year of construction: | 1982 |

| Compressive force: | 600 kN |

| Tractive force: | 600 kN |

| Piston stroke: | 250 mm |

| Pressure plate distance (max.): | 500 mm |

| Clamping distance: | 0 - 600 mm |

| Clamping range: | Ø 5- 64 mm 1 - 48 mm (flat) |

| Special accessories: | Load speed control Hasco temperature controller (Max. power consumption : 3.6 kW) |

Test equipment - Optical measurement

| Manufacturer: | InfraTec GmbH | ||||

| Detector format: | 640 x 480 infrared pixels | ||||

| Spectral range: | 7.5 - 14 µm | ||||

| Image frequency: | 50/69 Hz | ||||

| Temperature measuring range: | -40 - 1200 °C | ||||

| Resolution (therm.): | <0,03 K | ||||

| Measuring accuracy: |

| ||||

| Objective: |

|

Test equipment - coordinate and surface measurement

Machining and cutting processes - lathes

Machining and cutting processes - sawing and cutting

| Manufacturer: |

| ||||||||||||||

| Model: |

| ||||||||||||||

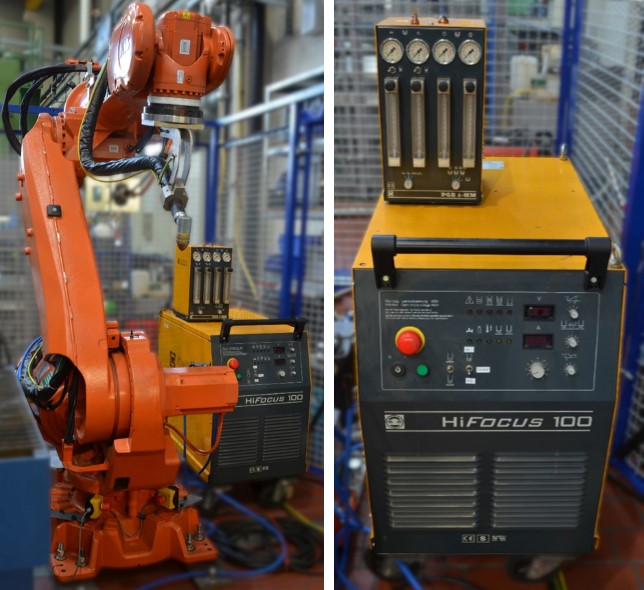

| Plasma cutter: |

| ||||||||||||||

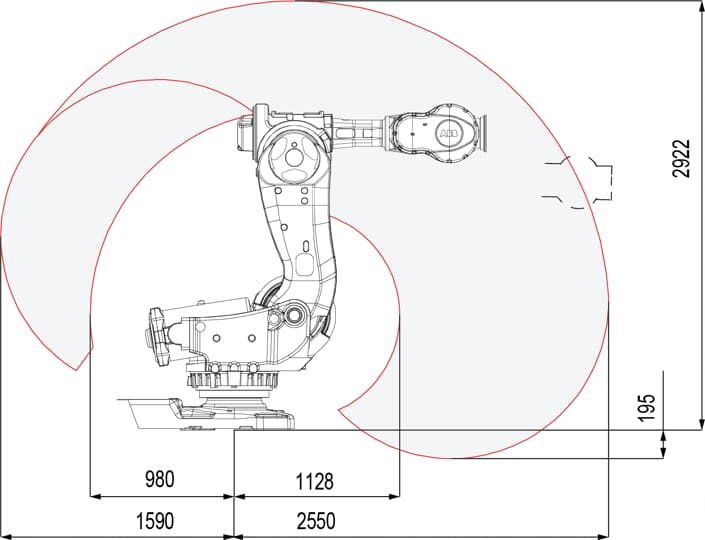

| Robot arm: |

|

Machining and cutting processes - milling and drilling

| Manufacturer: | DMG Mori |

| Axes: | 5 CNC (x,y,z,b,c) |

| Traverse path X-axis: | 550 mm |

| Traverse path Y-axis: | 450 mm |

| Traverse path Z-axis: | 505 mm |

| Swivelling angle B-axis: | -35° to +110° |

| Rotation angle C-axis: | 360° |

| Workpiece weight: | max. 300 kg |

| Workpiece dimensions: | ø500 x 390 mm ø400 x 440 mm |

| Table size: | ø505 x 500 mm |

| Control system: | Siemens |