Self-correcting production in connection and automation technology

Overview

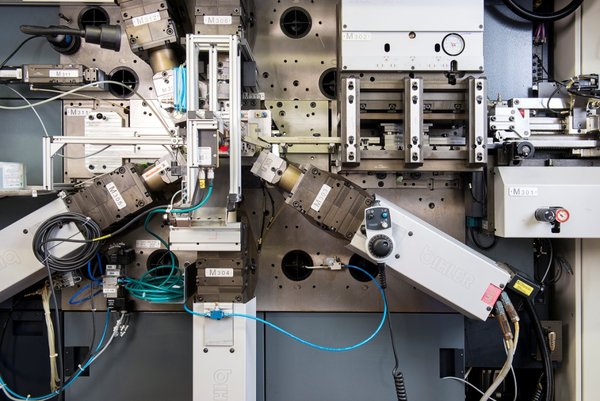

Electrical contacts are at the heart of electronic connection and automation technology components. As they are responsible for the reliable operation of machines and systems, high demands are placed on the precision of the small metal parts. These metal parts are manufactured using forming processes that are sensitive to changes in operating conditions such as material properties or temperature. In order to guarantee quality and keep rejects to a minimum, the production machines require complex institutionalisation. We are looking for processes with which the settings of the production machines can be automatically readjusted when the material properties of the raw material change. In future, the quality, reliability and efficiency of the forming process are to be optimised using innovative self-correction technologies.

The aim of the innovation project is to develop control strategies, sensors and actuators for self-correcting forming processes in the field of electronic connection and automation technology. In line with the guiding principle of Industry 4.0, the production machines for different products should adapt independently to changing operating conditions. The project results will increase reliability, quality and efficiency in the production of electrical contacts for electronic connection and automation technology.

The time and effort required to set up and retool the machines and the amount of waste will be reduced. The overall aim is to increase productivity and efficiency by 10%. The results can be transferred to other production processes, such as elements of the automotive and furniture industries. The technologies developed will be made available to other companies via transfer projects and engineering companies from it's OWL.