EECC technology development for energy-efficient tank construction

Overview

There is currently a high demand for a wide variety of pressure vessels, the production of which is characterised by comparatively complex and energy/raw material-intensive process steps and the resulting process chains. Tubular semi-finished products are often heated locally using fossil fuels (gas) and moulded using universal tools. These processes are comparatively inefficient, energy-intensive and not climate-neutral due to the use of fossil fuels.

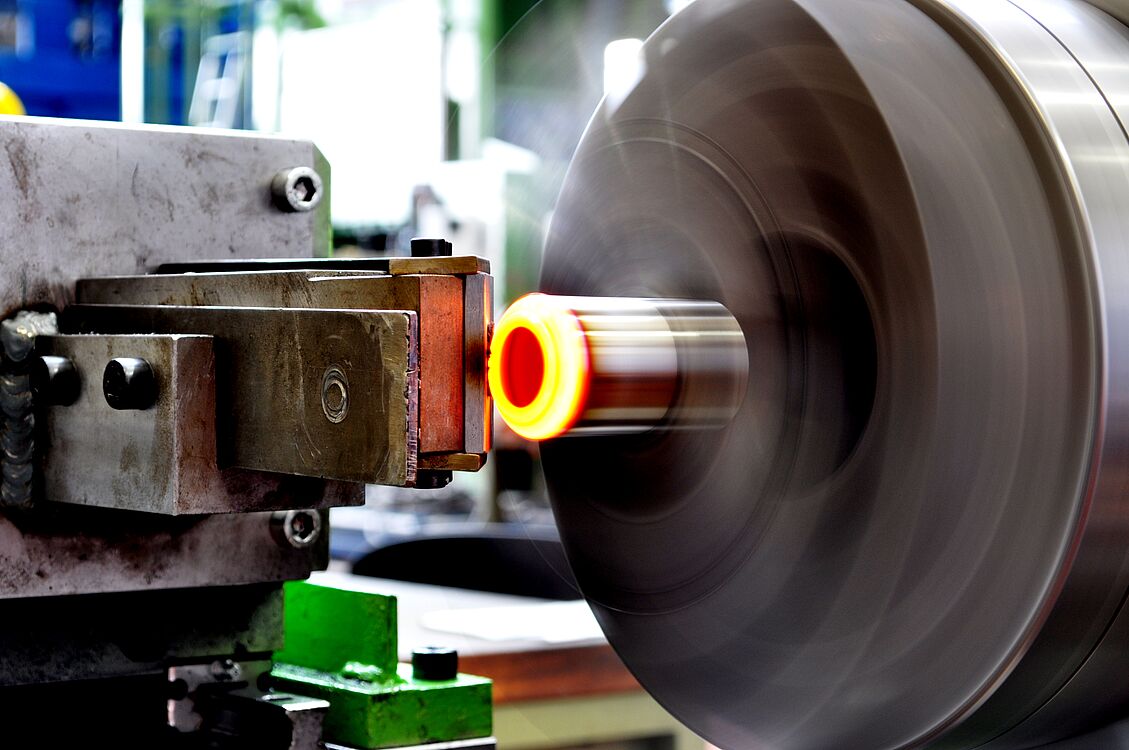

Extensive basic research at the Chair of Forming and Machining Technology (LUF) at Paderborn University has led to the development of friction spinning, a process that can flexibly form tubular and sheet metal semi-finished products using universal tools and kinematic shape generation. Process-integrated and localised component heating can significantly increase the forming capacity of numerous materials and ensure high energy efficiency. The energy required for this is generated electrically and not by fossil fuels, which can make an innovative contribution to a climate-neutral industry. Accordingly, friction spinning is an ideal starting point for realising the energy-efficient, climate-neutral production of innovative, high-performance products based on readily available standard semi-finished products.