Development of a production process for the economical series production of ultra-high-strength hybrid composite structures for weight minimisation in automotive engineering

Overview

The increased use of CFRP in large-scale production is expected to result in significant weight savings in the field of structural automotive components. In order to achieve the necessary cost reductions, two approaches are being pursued:

Localised use for targeted reinforcement with CFRP material.

This follows the lightweight construction principle of optimum material utilisation.

The development of suitable, cost-effective production processes for hybrid composite structures.

In line with the high proportion of production costs for CFRP components, the key to large-scale use lies in the development of cost-effective processes.

This overall objective can be divided into three different innovation stages, with the common goals of

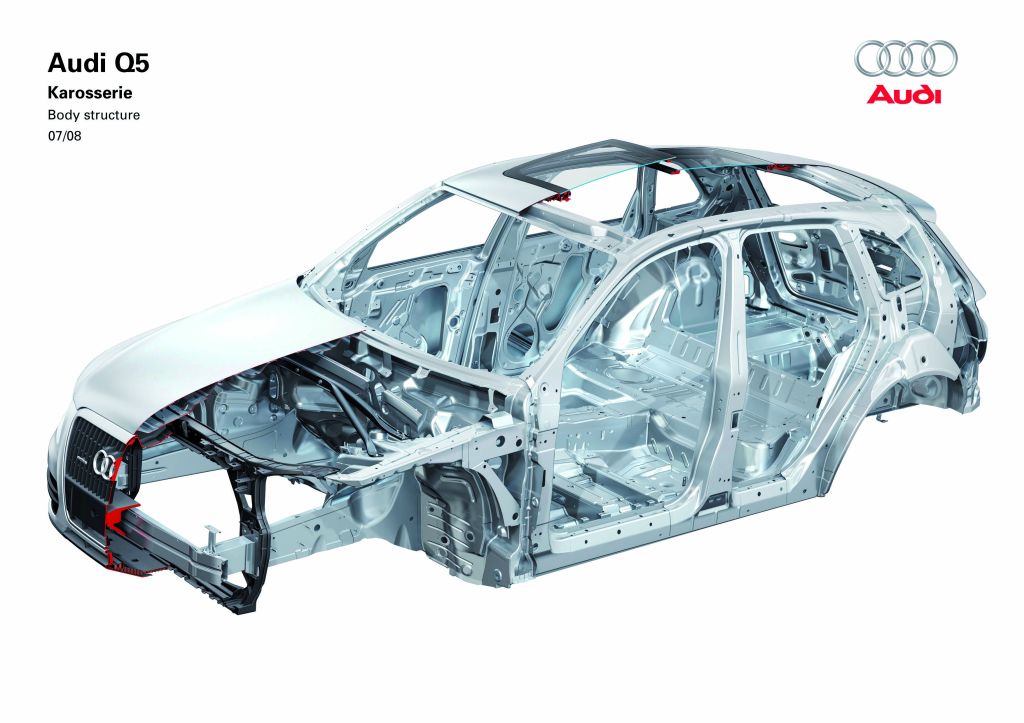

Identification and selection of automotive components that are optimally suited for the production of hybrid composite structures.

Determination and provision of data required for process simulations.

Design and simulation of the production processes for steel / CFRP hybrids.

Implementation of the findings in a process suitable for series production.

Innovation stage I:

- Development of a process suitable for large series production for the manufacture of components with local use of CFRP (combination of pressed steel part and cured CFRP moulded part).

Innovation stage II:

- Development of considerably more cost-effective processes for the production of components by means of the local moulding of prepregs (uncured CFRP starting materials) into steel components under presses or the combined forming of steel sheets and prepregs in one process step.

Innovation stage III:

- Development of processes for the production of complex (multifunctional) components by using new hybrid semi-finished products based on clad materials with localised CFRP reinforcements.