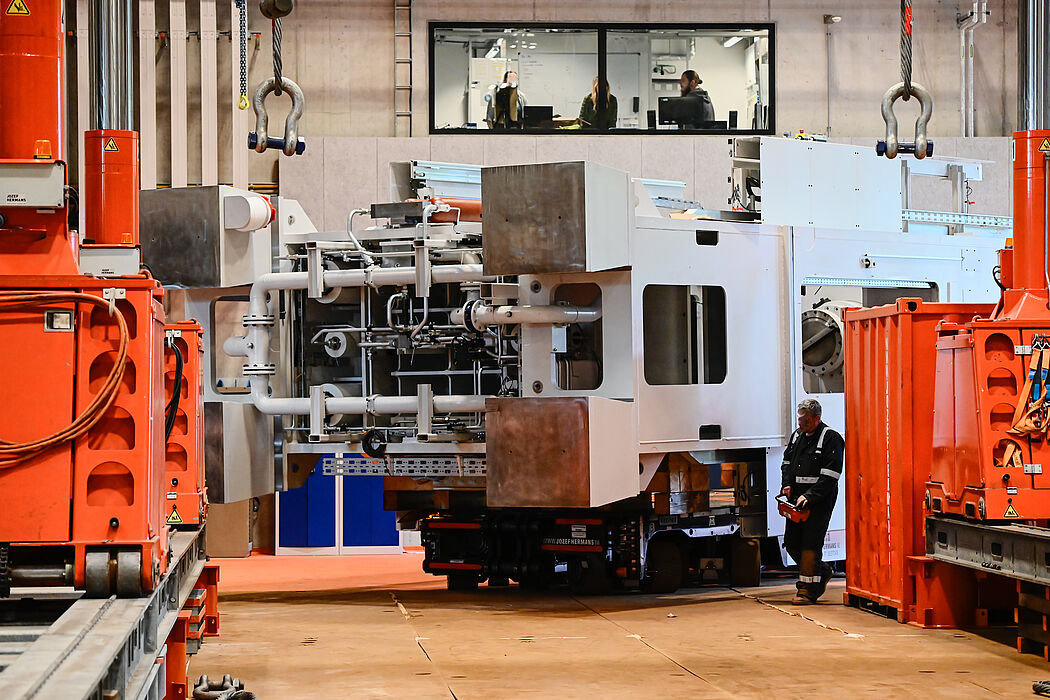

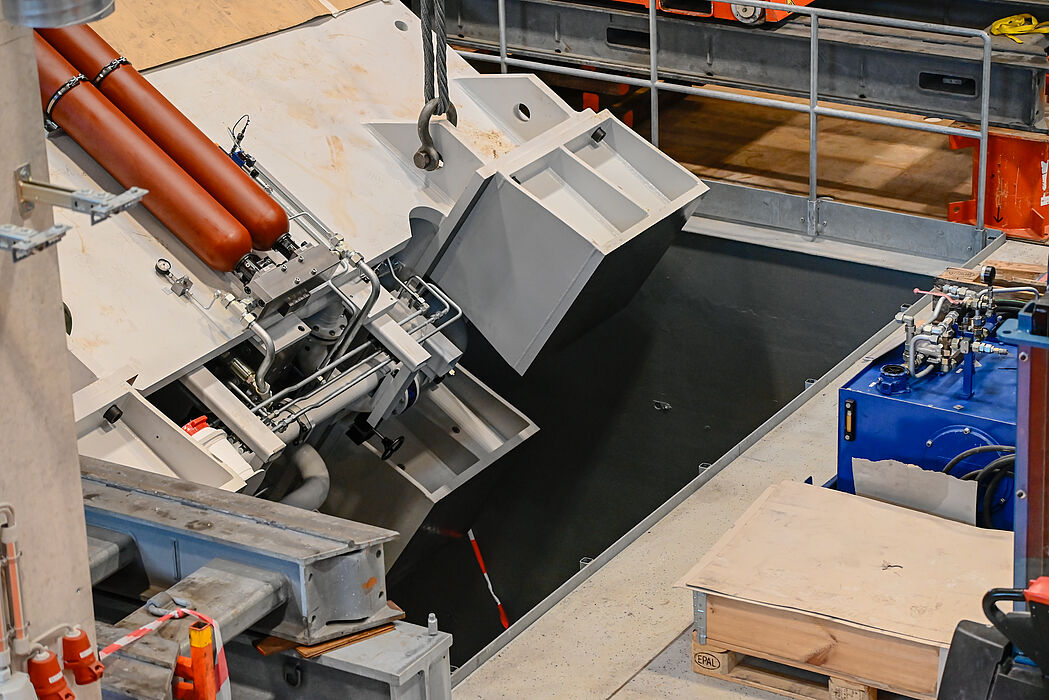

The new hydraulic universal press from Schuler has arrived. Logistical work on the Y building has already begun. The press will be put into operation over the next few weeks. The new Schuler hydraulic universal press with a pressing force of 10,000 kN will then become a central component of the test facility at the Institute for Lightweight Construction with Hybrid Systems (ILH) and part of an equipment upgrade at the Chair of Forming and Machining Technology (LUF). Future application scenarios include research and development of new forming technologies, particularly in the context of cross-disciplinary process chains for the manufacture of complex components made primarily from sheet metal composite materials. This is made possible by features such as the multi-point hold-down system, the high-resolution, proportionally controllable pressure setting, and the powerful press and process control system.