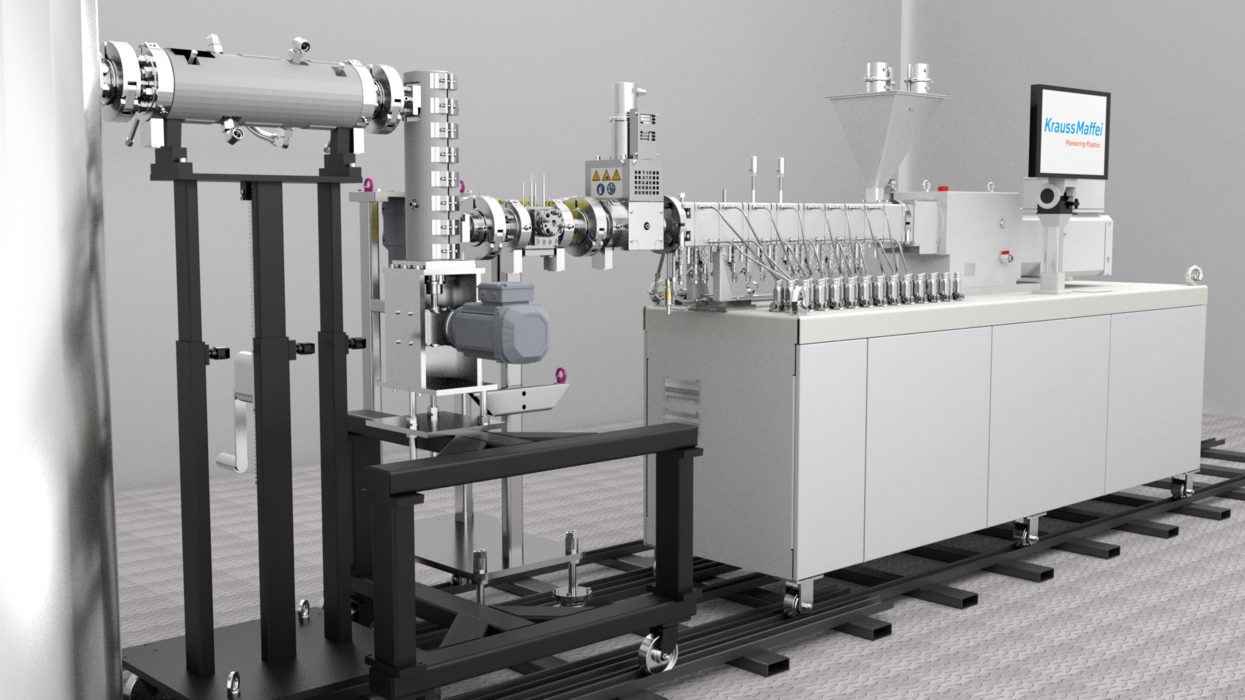

From 15 to 16 June 2020, the new twin-screw extruder for gas-laden plastic melts was put into operation. The co-rotator from the manufacturer "KraussMaffei Extrusion GmbH" was procured as part of the ERDF research project "iAMnrw Materials" and forms the core of the planned PGSS system, which will be used to produce powder for selective laser sintering (SLS).

In this process, a supercritical gas is added to the plastic melted in the extruder to reduce the viscosity of the plastic-gas mixture. The pressure in the system is then increased with the help of a gear pump to overcome the nozzle at the end of the extrusion line and at the same time suppress the foaming of the emulsion. To increase the homogeneity of the gas in the melt, a dynamic mixer is connected downstream of the pump. The mixture is then fed into a static melt-mix cooler, where it is further homogenised and cooled to a temperature just above the melting point of the plastic.

Because the viscosity of the melt has been reduced so much by the addition of the gas, the plastic-gas mixture can finally be sprayed through a nozzle. With the accompanying relaxation or expansion of the gas, the plastic phase is torn apart so that spherical particles form due to the surface tension. At the same time, the Joule-Thomson effect occurs due to the drop in pressure, which causes the spherical particles to cool rapidly and solidify into powder particles. The spherical shape is an important material requirement for laser sintering powders, which is only given to a limited extent by competing manufacturing processes.