Research development enables international collaboration in the machinery room

The skills shortage is becoming increasingly acute. Scientists at Paderborn are examining how augmented reality (AR) can help tackle this challenge: under the ‘AR Service System’ project, they are developing a technology that enables specialists to guide machinery operators in production despite (still) working remotely from the company site. With this AR solution, local companies will be able to access support from specialists all over the world and integrate them into their working processes. Researchers from the ‘Product Creation’ research group at Paderborn University’s Heinz Nixdorf Institute worked on the project with the plastics processing company Hadi-Plast GmbH in Hövelhof. The six-month project, which received around 30,000 euros of funding from Projektträger Jülich (PtJ), was successfully completed at the end of March.

AR support for industry

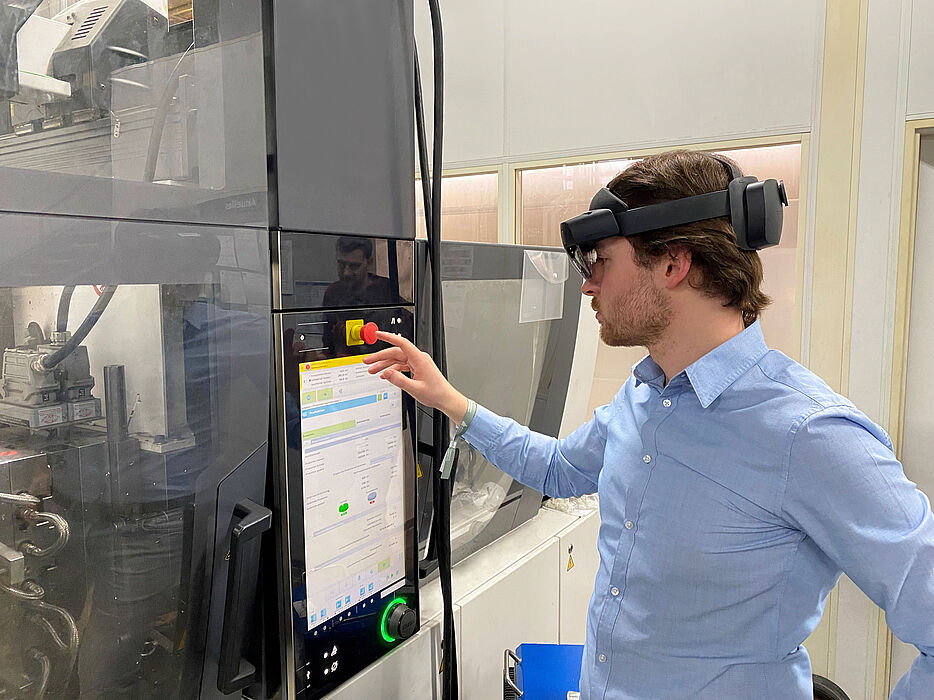

Augmented reality is a growing trend in industry. Relevant applications help with simulating test drives or designing prototypes. The Paderborn project team has conducted extensive testing in another area of application. Using AR glasses that supplement our reality with virtual representations in the field of vision, digital objects can be inserted into a real environment – e.g. if an employee is standing in front of a machine in the production hall. "For example, an external employee can use this AR application to say ‘press this button I have marked here‘, thus minimising the effort of explanation", notes Philipp Hesse, research associate in the ‘Product Creation’ research group led by Prof. Iris Gräßler at the Heinz Nixdorf Institute. Another benefit of this technology is the fact that the glasses ensure that the in-house machinery operator’s hands remain free, enabling them to react quickly, easily and flexibly. The external specialist sees exactly what their colleague onsite sees in real time, allowing remote employees to effectively intervene in the production process as well as enabling new colleagues to learn at the company premises.

Optimising processes using digital assistance

Hesse describes how the idea for the project came to be: "Hadi-Plast GmbH uses a process for making its plastics that requires special skills – injection moulding. This process involves melting plastic granules and injecting them into a steel mould under pressure. Specialists in this area are rare and in high demand. This means that it is often necessary for companies in this sector to incorporate external experts into these special work processes."

With the AR application, the project team has found a solution to this problem. The technology enables Hadi-Plast to operate machinery at various sites that is all supported by injection moulding experts without their having to be onsite everywhere and all of the time. The specialists can handle complex tasks at multiple sites or train staff without becoming unavailable elsewhere. Another opportunity for using this to combat the skills shortage arose when a company employee emigrated. The AR solution means that they can continue working for the company as a process mechanic across state borders.

Various technical solutions were extensively tested with machine operators and apprentices at the company, as well as with specialists abroad. The test phase ultimately led to the final solution, involving the use of the AR application.