The SIGMA simulation software is a joint research project between leading industrial companies and Kunststofftechnik Paderborn. The program is used to simulate compounding and processing operations on co-rotating twin screw extruders. This year, the SIGMA user meeting was held for the second time as a digital event on March 11. Here, Kunststofftechnik Paderborn presented the new SIGMA version 13.1 and the new features it contains to the project partners.

These include software-technical improvements such as the temporary deactivation of material additions, the implementation of transition threads and an improved visualization of strand cooling. Also presented were the newly implemented Screw Design Rules and modeling for the molecular weight degradation of PP in the twin screw extruder. In addition, users were shown the latest enhancements to SIGMA3D and the development status for three-dimensional flow simulation of partially filled screw elements with Extrud3D.

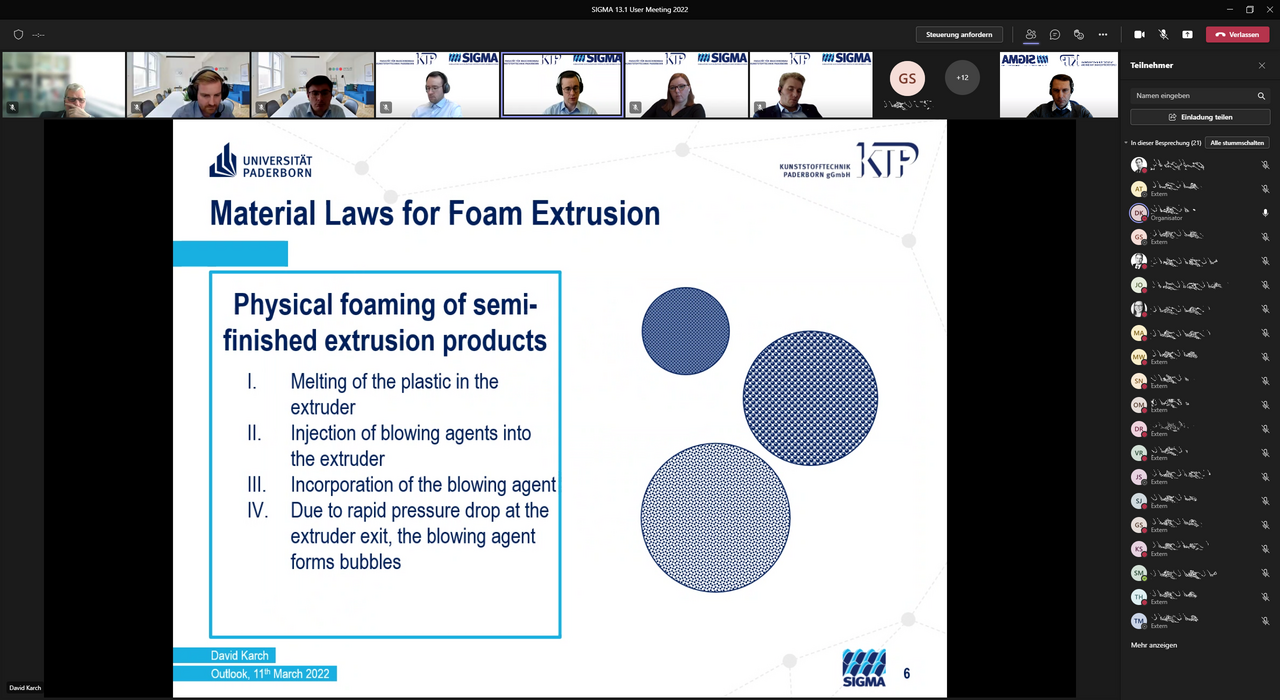

The event ended with a presentation of the work scheduled for SIGMA 14. The next SIGMA project is expected to include, for example, novel modeling for energy input and torque calculation of individual screw mandrels and elements, implementation of material laws for foam extrusion, and development of automatic process optimization. Through the exchange with the participating project partners, additional suggestions for the further course of the project could be collected.

Present were company representatives from BASF, Brückner Maschinenbau, Covestro Deutschland, Evonik Industries, KraussMaffei Extrusion, Leistritz Extrusionstechnik and Reifenhäuser Extrusion Systems.